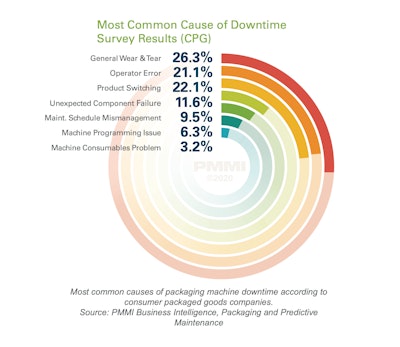

Predictive maintenance is the ability to monitor a machine, or machine component, and avoid unplanned downtime by foreseeing machine failure and allowing the opportunity to take preventative action. The possibility of machine failure shutting down a production lines ranks high on most manufacturing managers’ list of worries, and report research showed that manufacturing managers at CPG companies consider their packaging machines to be more prone to downtime than the other types of machines they use. CPGs report packaging machinery more prone to downtime than other types of machinery

CPGs report packaging machinery more prone to downtime than other types of machinery

According to “Packaging and Predictive Maintenance,” most of the predictive maintenance solutions currently on the market are designed to monitor critical assets such as AC induction motors, pumps, and gearboxes; and they tend to be based on vibration sensor solutions.

The critical functions of packaging machinery, however, tend to be under servo control, even though many machines do employ standard AC motors. Servo technology does not lend itself to vibration monitoring, so OEMs are currently using thermal imaging to gather necessary data on servo systems. It is expected that in the future, predictive maintenance opportunities will be built directly into the servo drive, allowing for standard predictive maintenance solutions to be applied.

Some types of packaging machinery are more prone to downtime than others, and CPGs reported interesting results with regard to which are most likely to break down. In the “extremely likely” category, form, fill & seal machines were reported in the lead – with 14.3% of manufacturing managers at CPG companies rating them as extremely likely to suffer downtime. Next reported in the “extremely likely” to fail category are labeling, decorating, and coding machines – which were placed in this category by 13.3% of respondents. The types of packaging machinery most likely to fail, as reported by CPGs.

The types of packaging machinery most likely to fail, as reported by CPGs.