This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

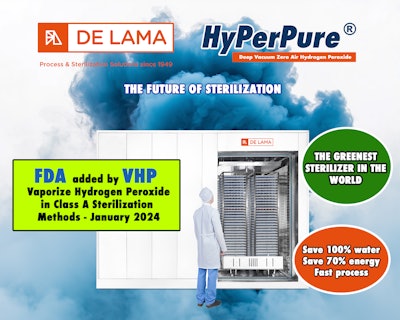

HyPerPure is a cold sterilization system for solid and porous products. As a choice for an alternative to EtO (Ethylene Oxide) and Gamma Rays, HyPerPure represents a green sterilization solution on the market.

HyPerPure Sterilization technology is a proprietary solution by De Lama operated with De Lama DLVHP/ST equipment and covered by international patent together with its HyPerGeneSys H202 generator

It’s a low-temperature sterilization process representing the real alternative to EtO (Ethylene Oxide) and Gamma Rays sterilization, and offering advantages compared to these more traditional techniques.

Thermo-labile finished products can be sterilized into recessed cavities.The use of the vacuum technology allows gas to penetrate into a variety of packaging. The vacuum system is composed of multiple step high vacuum systems to allow the sterilization phase and gas removal at cycle end.

The sterilization cycle work in an open loop, without any consumables, and allows a high level of repeatability

Using HyPerPure with De Lama’s proprietary peroxide generator, HyPerGeneSys makes for effective use. It's a H202 generator that is able to operate in a high vacuum and operates by acting with an electromagnetic field capable of ionizing the peroxide molecules in order to increase their lethal effect on microorganisms.

Main Features:

- It's a sterilization system with LOG 12 reduction.

- The Vaporized Hydrogen Peroxide solution has industrial possibility: we span from 150 Its chamber to 90 cubic meters. The bigger sizes can replace other technologies and typical EtO chamber size required by manufacturers.

- Every chamber is customized in size and shape according to customer request. There is no fixed size catalogue with 2,3 or 5 models, 150 lts up to 90 cubic meters.

- An alternative to Eto (Ethylene Oxide) sterilization and gamma rays.

- It's supported by regulations, January 2024 FDA added Vaporized Hydrogen Peroxide among the class A sterilization methods.

- It's internal in the production plant. It isn't explosive or a pressure vessel.

- Eliminates cost and time related to external contractors for sterilization.

- The average process time spans from 3 to 5 hours reducing EtO typical 48-72 hours time.

- The cost of capex is lower than an EtO plant.

Comparison with EtO (Ethylene Oxide) Sterilization and Gamma Rays sterilization:

- 0 Polluting Emissions: H202 is divided into Water and Oxygen molecules at the end of the cycle and released in the environment

- 100% Water Saving when compared with saturated steam sterilization

- 70% Energy saving when compared with saturated steam sterilization

- 70% CO2 Reduction when compared with saturated steam sterilization

The process is at a low temperature with no thermal energy waste that occurs in hot sterilization processes. There are no liquid discharges towards the installation environment. There is no water consumption and low energy consumption.

MAIN STERILIZATION APPLICATION

The process of packaging products such as syringes filled in aseptic, can now be done by eliminating the use of the expensive Class A (or B) clean room.

Although the contents of the syringe have been previously sterilized, legislation stipulates that the air inside the packaging and the external surface of the syringe must be sterile.

With the autoclave proposed by De Lama, Hydrogen Peroxide, by means of a strong vacuum, is able to penetrate the packaging and to penetrate multiple layers surfaces such as Tyvek (or medical paper), thus sterilizing the environment inside the package and the external surface of the product.

Specific packaging with one side in Tyvek (or medical paper) , once extracted by autoclave, even if the operation is realized in a non-classified area, preserves the sterile environment inside packaging created by sterilization process through Hydrogen peroxide made with DLVHP/ST.

To carry out this sterilization it is sufficient to insert the packages in the chamber and start the cycle. All of this can occur in a lower classification environment, avoiding the costs of environments classified as high-level aseptic. and multi-component implants:

The deep penetration of Hydrogen Peroxide and its cold process, Sterilization through De Lama DLVHP/ST is a solution for prosthesis for implants of various materials and for different surgical applications — knee, ankles, elbow, and jaw —and multi-component implants: pace-makers, defibrillators, and cochlear implants.

De Lama is available to test the sterilization of every single prosthesis produced in order to verify the sterilization also in the inner parts and holes for objects with a complex design and also to verify the complete material compatibility with Hydrogen Peroxide.

HyPerPure sterilizer is able to sterilize the pieces of the filling line inside the isolator. This process can be made by a DLVHP/ST equipment standing alone, or directly connected with an isolator.