Icy Hot Smart Relief for back pain sufferers stands out on store shelves in a thermoformed pack with outer card that holds the reusable, wireless battery-powered device, customizable in 63 different intensity levels.

Icy Hot Smart Relief was introduced in 2014 by Chattanooga, TN-based Chattem, the U.S. consumer healthcare division for Sanofi. In this Q&A article, Nancy Limback, Sanofi Manager, Package Development and Innovation, discusses the package design and development process for the product.

HCP: Is this a new product or is it new packaging for an existing product?

Limback: The Icy Hot Smart Relief product is new product for Chattem. Smart Relief, an extension of trusted brand Icy Hot, delivers portable, powerful pain relief for persistent, chronic aching back muscles—even arthritis—through a small, wireless battery-powered device. The device uses Transcutaneous Electrical Nerve Stimulation (TENS) technology. TENS is a clinically proven method routinely used for decades by doctors and physical therapists, to block the body’s pain signals by sending gentle electrical pulses along the nerve to intercept pain signals before they reach the brain. It also stimulates endorphins, the body’s natural pain reliever.

With the product’s entry into a relatively new category, it was imperative that the packaging was designed to stand out to ensure our consumers could easily identify it. This differentiation in packaging was achieved through the shape of the package and its graphics, including vivid colors on a black background, a high-gloss UV finish and foil stamping. Icy Hot Smart Relief began shipping at the end of February 2014, with retail sales critical mass taking effect in the second quarter of 2014.

HCP: What do the products require in regards to packaging structure? What are the concerns regarding water/moisture barrier, shelf life, protection during the supply chain, shelf presence, etc?

Limback: The Icy Hot Smart Relief packaging was developed by a cross-divisional, cross-functional team, including Sanofi Package Development, Chattem Marketing, R&D and Operations, Sanofi Legal and key vendor partners.

Sanofi Package Development led the efforts to develop a detailed Design Input document, which included all of the key deliverables for the packaging at the start of the project. Chattem Marketing and Sales provided background about the Icy Hot consumer. The R&D team led the effort around establishing product environmental protection requirements. Barrier requirements were satisfied through the resealable pouch used for the electrode pads. The package protection requirement throughout the supply chain process remained in tact. Package Development did considerable lab-based testing to ensure the package and product would arrive home with the consumer in an undamaged, unaltered state.

Testing included distribution challenge qualifications, multiple actions of opening and securely reclosing the clamshell, and the Velcro on the sleeve, as well as the security of the tamper-evident seal over different temperature and humidity conditions.

HCP: Is this product manufactured by Sanofi?

Limback: No, this product is outsourced to two countries outside the U.S. The Icy Hot Smart Relief TENS control unit, electrodes, batteries, and literature are all shipped to a contract packager, Witko, Inc. The thermoforms and paperboard components are manufactured by Rohrer Corp. and are also shipped direct to Witko. The packaging for the retail starter kit, the refill kit, and the club pack is done on semi-automatic lines. Packaging into the clubstore displays is done at Chattem in Chattanooga, TN.

HCP: What components make up the package, and what is the purpose of each?

Limback: There are three SKUs that make up the Icy Hot Smart Relief product line. The packages are consistent in their unique curved appearance and graphics that reinforce the brand and make it easier for our consumers to find on shelf:

The Starter Kit includes a custom thermoform clamshell with thermoform insert, tamper-evident seal, and paperboard sleeve with a fifth panel. The package contains one control unit, one electrode pad, two electronic security tags, and three pieces of consumer literature.

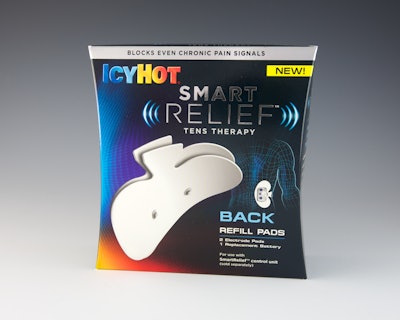

The Refill Package includes a curved paperboard carton with tamper-evident seals on the tuck ends. The package contains two electrode pads and a replacement battery.

The Club Pack includes a custom thermoform clamshell with thermoform insert, a tamper-evident seal, and a paperboard sleeve with a fifth panel. The package contains one control unit, six electrode pads, five replacement batteries, and three pieces of consumer literature.

The custom thermoform system was developed to address the requirements of differentiation on store shelves, reinforcement of the brand identity–specifically the contemporary graphic curved “pulses” graphic, product protection, shelf size restrictions, durability in distribution, etc. The packages can standalone as well as operate within various retail-shelf pusher systems. The thermoform inserts keep the control unit and electrode pads snuggly in place.

The clamshells serve as protection for the product and as reusable storage cases for the consumer. The consumer can slip the sleeve back over the clamshell or fold it flat for storage. Repeated distribution challenge testing as well as usability testing were used to modify/perfect the fit and function.

The dynamic vivid graphics represent continuity of the Icy Hot brand line within this new product category. The foil stamping is used not only to differentiate on store shelves, but also to reinforce the premium-quality image of the product. The retail clamshell features a curve on the right side, which nests with the curved refill pack on shelves. The electrode pads are supported by a curve in the interior of the retail clamshell for protection, and serve as a tool in meeting the overall shelf height restriction. The sleeve provides an abundant area for graphics, which can be recognized easily on shelf by the consumer. The fifth panel on the sleeve is closed with flat-profile Velcro.

HCP: How do you balance the need for packaging protection and shelf appeal with the need to be environmentally responsible?

Limback: The consumer-driven design requirements were definitely a priority, however they were balanced with sustainability in mind addressed through the reusability of the clamshell system and the materials selected for use.

The result was a package that was not only environmentally responsible but functional and inviting for the consumer.

HCP: What packaging materials were selected for greater sustainability?

Limback: Sustainability was one of our design inputs. The sleeves (retail and club) use less paperboard than similar-sized standard cartons and are made from SBS board that has been certified by the Sustainable Forestry Initiative (SFI). The thermoforms (retail/club and clamshells/inserts) are made from Recycled Polyethylene Terephthalate (rPET), which uses a minimum of 40% recycled PET resin content. Also, the clamshells are recyclable and reusable for storage of Smart Relief or other items.

HCP: How does the packaging for Smart Relief compare with the packaging of competitive products in the marketplace?

Limback: The Smart Relief packaging stands apart from the competitor’s packaging of over-the-counter TENS products with its unique sleeved clamshell and nested refill pack design. The consumer can view the Smart Relief control unit and has access to abundant detailed information on-shelf about its use and benefits.

HCP: Was consumer input considered when developing the design?

Limback: We conducted both Qualitative and Quantitative studies to understand the tradeoffs between different packaging types as well as several graphic overlays. Since this was a relatively new OTC product category, Chattem Marketing felt strongly that clear detailed educational information should be provided and accessible to our consumers on-shelf. The storage function of the clamshells was considered an important added value for our consumers.

We were able to narrow the options; we looked at it from the Qualitative approach we conducted with pain sufferers and refined it to a few options that we then tested in a Concept Optimization exercise that was Quantitative for both graphics and structure type. Thus, the packaging type we arrived at was vetted for basic visual and functional attributes that informed the design brief, and then further refined with the team as we went through the design and development process.

It was important that the Smart Relief TENS unit was visible on store shelves and the reclosable front cover of the sleeve was implemented as a method to provide additional graphic space for onshelf consumer information/education about this new product.