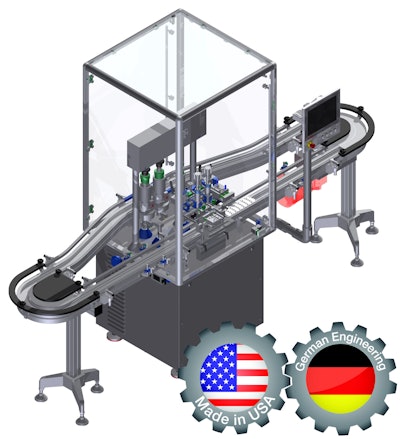

Groninger has launched its “groninger lite” line with the first model EBF 102L, an automated filling machine designed for small private-label companies, R&D, as well as contract manufacturing. “Groninger lite” fills the gap in the machine portfolio between manual tabletop units and fully automated high-speed production lines, offering filling and closing equipment for all sizes of businesses and budgets.

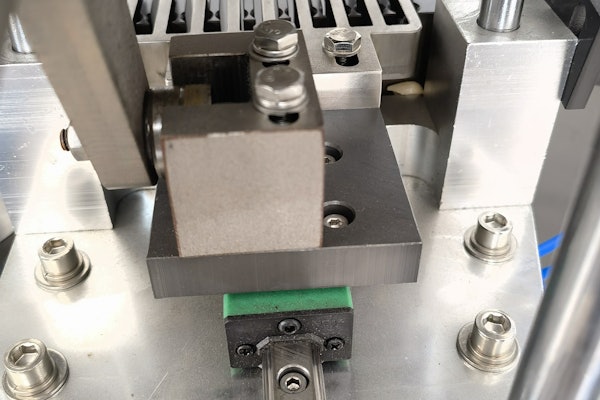

The two-headed filling unit can fill up to 2,700 units/hr with a filling range up to 16 oz.

Glass and plastic containers of all sizes and shapes can be processed within pucks or puck-less. The machine features easy and quick changeover between sizes, a 12-inch touchscreen HMI, and a sturdy design.

The new “groninger lite” was developed and produced in groninger’s U.S. headquarters in Charlotte, NC.