Key takeaways:

· Yundu Machinery Technology Co., Ltd. is a contract manufacturer dedicated to the health and wellness sector.

· Its production floor was centered around two reliable but aging semi-automatic capsule fillers.

· After the new equipment installation, production capacity increased from 20,000 to 72,000 capsules/hour.

Yundu Machinery Technology Co., Ltd. is a contract manufacturer dedicated to the health and wellness sector. According to the co-man, the company partners with various brands to produce high-quality encapsulated supplements and nutraceuticals.

“Essentially, brands trust us with their formulas, and we turn them into finished, market-ready products under strict quality control,” says John Smith, Operations Manager for Yundu.

For years, Yundu’s production floor was a hub of constant activity, centered around two reliable but aging semi-automatic capsule fillers. This setup required a team of four skilled operators who worked diligently every day to manually handle trays of capsules, oversee the filling, and then move everything to a separate station for polishing.

“It was a very hands-on process,” says Smith. “While it served us well for a long time, we were reaching a clear ceiling.”

Smith says that the production was maxed out, and maintaining perfect fill consistency across every single batch was a constant challenge, sometimes leading to higher-than-desired rejection rates. But this isn’t what finally gave the company the nudge it needed to install fully automatic capsule filling equipment. The real turning point came when Yundu was presented with a massive opportunity: a contract with a major national retailer that would require the company to triple the production output, almost overnight.

“It was a game-changer, but it came with a significant demand. We knew immediately that our existing process wouldn't just be strained; it would be impossible to meet the demand,” says Smith.

Additionally, Smith said that the company needed to improve its GMP (good manufacturing practices) compliance and ensure higher product quality and consistency to meet the retailer's standards.

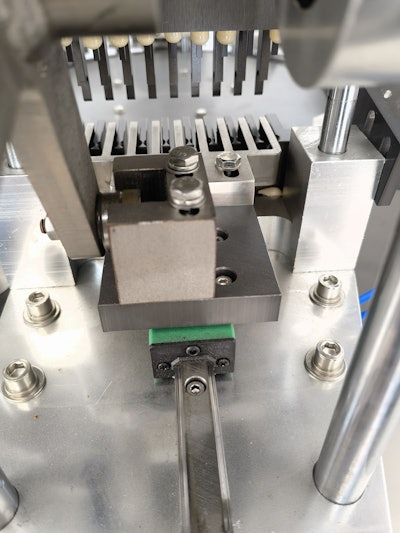

All of this is what led the company to turn to Grand Intelligent Equip. and install its fully automatic NJP-1200 capsule filling machine. This single, integrated solution is capable of handling everything from orienting the empty capsules to filling, closing, and polishing them in one seamless flow.

“The impact of this upgrade was felt across the entire operation,” says Smith.

From Bottleneck to High-Speed Throughput

The most dramatic change was, of course, the speed. After the equipment installation, production capacity at Yundu increased from 20,000 capsules/hour to 72,000 capsules/hour.

“We went from a process that felt like a constant struggle to keep up, to a smooth, continuous flow that increased our overall production capacity by well over 200%,” says Smith.

A More Strategic Use of Labor

Another noticeable benefit was how labor was utilized. What once required four operators handling the manual, repetitive tasks, Yundu now has a single operator overseeing the entire automated line.

“We reassigned three of the four operators to other value-added tasks, saving approximately $120,000 annually in labor costs,” says Smith.

According to the company, those experienced team members were reassigned to strategic roles within the company, such as quality assurance and machine maintenance where their skills could be better utilized. This move not only saved the company money but was a “huge win for efficiency.”

Improved Quality and Consistency

The precision of the NJP-1200 was another major improvement. The automated dosing system delivered a level of fill accuracy that Smith says is incredibly difficult to achieve manually. The improved fill accuracy to ±2% has meant significantly reduced powder waste and product rejection rates.

“This meant product quality became more consistent than ever before, and we wasted far less of the expensive raw materials we work with,” says Smith.

Additionally, the integrated polishing station eliminated a separate manual step.

Long-Term Future Brand Implications

Smith say that the ability to meet higher production demands allowed the company to win the new retail contract, boosting brand presence nationwide. The company is able to meet the new contract's demands, while also adding the bandwidth to take on other new clients. In essence, the NJP-1200 wasn't just a machine upgrade for Yundu; Smith says it was a fundamental business transformation.

“It gave us the capabilities to operate on a new level, secure a landmark contract, and solidify our reputation as a high-volume, high-quality manufacturing partner,” says Smith.