Although most conveying systems used for end-of-line packaging operations run at less than 300 ft/min, faster conveyor speeds could sometimes be utilized on straight conveyor sections for high-volume throughput of lightweight, low-profile products. Shuttleworth, Inc., has released high-speed, chain-driven conveyors capable of reaching speeds up to 495 ft/min, while maintaining product stability. This allows manufacturers added versatility on their packaging lines, should they require the added conveyor speed. The conveyors can be specified for cleanroom 100 use.

Speeds are achievable, in part, because of improvements made in wear and friction engineering, particularly with its effect on plastics, which represent a critical component to longevity in conveyor operation. Faster speeds produce higher force vectors, which can increase wear on conveyor components.

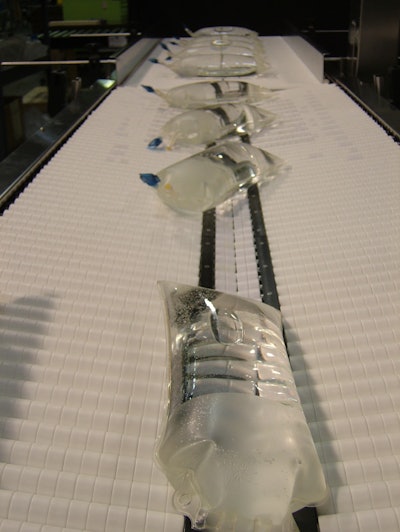

Utilizing the latest controls technology of PLCs, motion control devices, servo motors, and variable-speed zoning, Shuttleworth conveyors provide gentle product handling and precise product placement, particularly for use in the food, pharmaceutical, electronics, and printing industries.

The high-speed conveyors can also be integrated with the company’s patented Slip-Torque® low-line backpressure technology for handling delicate products, and its Servo-Infeed® technology for ultra-precise product infeed, such as into wrapping equipment.