This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Woodstock Sterile Solutions, a blow-fill-seal (BFS) contract development and manufacturing organization (CDMO), is expanding its BFS capabilities by investing $8 million in a automated, high-speed bottle packaging line at its facility in Woodstock, Illinois.

The market for BFS technology is forecasted to grow over the next decade. According to Future Market Insights, the BFS market was valued at an estimated $3.1 billion in 2024, and they predict that the market will grow to $5.26 billion by 2034, representing a 5.1% compound annual growth rate (CAGR).

“There is currently a lack of CDMO capacity for BFS manufacturing in the United States,” said Nick Buschur, CEO of Woodstock Sterile Solutions. “This limited access is creating challenges for drug manufacturers, as rising production costs and supply chain inefficiencies hinder their ability to obtain domestically supplied, yet affordable BFS manufacturing services. Our investment will help to address this gap as we offer more cost-effective manufacturing and packaging solutions to current and future customers."

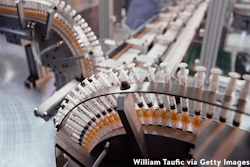

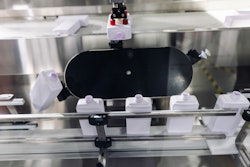

The new, high-speed bottle packaging line will enhance production efficiency, introducing capabilities that will allow Woodstock Sterile Solutions to package bottles with inline serialization, at a rate of 250-300 ppm. The Serpa line is capable of running 5 mL and 10 mL oval and round multidose bottles. Once completed, this investment will add an incremental packaging capacity of approximately 85 million units, supported by our 24/7 operations.

Using Woodstock’s BFS technology, primary containers are formed, aseptically filled, and sealed in a matter of seconds through a continuous automated process. This system provides sterility assurance and reduces contamination. In addition, Woodstock’s BFS technology allows for customized container design, accommodating a broad range of finished product types. Woodstock Sterile Solutions has delivered BFS solutions for its customers for more than 55 years covering a wide range of applications including respiratory, ophthalmic, topicals, biologics, oral liquids, pediatrics, diagnostics, and others.

Woodstock Sterile Solutions expects the new bottle packaging line to be installed in 2025 and can begin packaging in the first quarter of 2026.

“We recognize the cost and domestic supply challenges facing the industry and we are dedicated to providing solutions that address our customers’ needs. This investment enhances our operational efficiency, improves cycle times, and builds on our capacity. As a US-based, pure CDMO, we remain committed to our core focus of delivering high quality, flexible BFS solutions,” said Buschur.