This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Hurst Corporation and F.P. Developments, both American companies with over 60 years of experience in their respective industries, announce their partnership in the re-launch of the LabelStripper. After decades of collaboration, Hurst Corporation has selected F.P. Developments to manage the sales, marketing, innovation, manufacturing, delivery, and training of all Hurst label removal products. This partnership brings the LabelStripper under the management of F.P. Developments, continuing as a reliable, low-cost solution for efficient label removal.

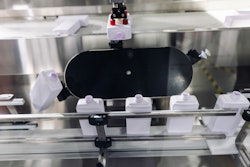

The LabelStripper offers a versatile and cost-effective solution for businesses in pharmaceutical, nutraceutical, clinical trial, and R&D sectors. This user-friendly machine accommodates a variety of glass vials ranging from 10mm to 100mm in diameter and up to 350mm in height, and can process up to 600 vials per hour—10-20 times faster than manual scraping. It improves ergonomics and safety while maintaining batch integrity and reducing labor costs, offering a high return on investment for manufacturers.

Key features of the LabelStripper:

- Up to 600 vials per hour processing speed

- 10-20x faster than manual scraping

- Improved ergonomics and safety

- Maintains batch integrity

- Decreases labor costs and offers high ROI

- Validation support available

- Small footprint

- Low maintenance

The LabelStripper is a solution for companies needing to remove labels from glass vials. Its design is tailored to meet the demands of pharmaceutical and nutraceutical manufacturing, clinical trials, and R&D facilities by providing an efficient, safe, and cost-effective alternative to manual label removal methods.

“We are excited to continue our longstanding relationship with F.P. Developments, a trusted partner who has always been at the forefront of innovation and customer service,” said Max Hurst, CEO of Hurst Corporation. “Their expertise in manufacturing, training, and support will ensure the LabelStripper remains a valuable asset for our customers.”