Invest in premium equipment to deliver affordable drugs.

It may seem counterintuitive. But it’s how nonprofit innovator Civica is approaching its mission to deliver quality generic medicines to patients in need. They are the only pharmaceutical company created for the express purpose of preventing and mitigating drug shortages.

I remember covering Civica’s talk at the PDA Annual Meeting in 2019. Having recently launched, they had identified a set of generic drugs to focus on and were working to contract with manufacturers or sub-contractors to produce drugs in established facilities. Their long-term goal was to produce their own nonprofit drugs. Just five years later (not long in the pharma world), here they are starting engineering and exhibit batches in their own new injectable drug facility in Petersburg, VA.

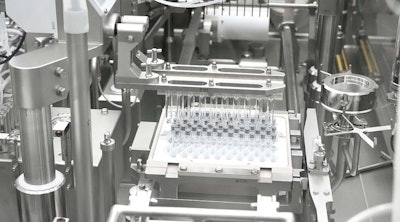

When they needed to purchase two filling lines for the facility, they turned to groninger, Germany-based provider of filling and closing machines, and Switzerland-based SKAN, known for their isolator technology. The new isolator-integrated vial filling line and nest filling line allow Civica to produce many different forms of injectables to be able to pivot based on greatest market need. They’re even filling a pen product in a nested tub cartridge successfully.

Jason Winfield, director of engineering, Biologics at Civica, credits the executive leadership team for prioritizing the approach to “do things right the first time.”

While it may be tempting to save money upfront in production, if this leads to rejects due to filling accuracy or quality issues, that ultimately costs more down the road and negatively impacts sustainability. Rejecting substandard product is the responsible thing to do, but if you can eliminate rejects from the outset, you save all the commodities you used in the process.

Continue to the full article here.