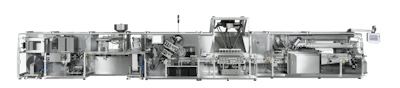

With the banner, “Always the highest quality—and always at full speed!," Mediseal presents its new high-speed cartoner, extending the company's offering for secondary packaging machines with a genuine high-speed product.

In numerous discussions, Mediseal heard a need for even faster cartoners. The P5000 high-speed cartoner now offers the right solution for our high-speed blister machines. This now extends from highly flexible systems such as the “White Line,” where the blister, leaflet and box can be custom-printed, to high-speed cartoners. All of these feature tried-and-tested Mediseal quality, because when the P5000 was being developed, it was based on the platform and components of the established P3200 cartoner.

The width adjustment on the product stack infeed and the carton height adjustment are automatic, enabling a fast format change. All areas of the cartoner are accessible for the operator and can be cleaned quickly when the product changes. This applies also to the slide-in module, which is unique in the market. This module pivots out completely, facilitating quick format changes and troubleshooting. The established design of the hinged functional elements on the P3200 cartoner has been retained.

In combination with the extensive format range, the P5000 stands for maximum productivity: with 120 mm separation, 500 cartons/min is possible, with a maximum folding box size of 90 x 110 x 200 mm. With 180 mm separation, available as a machine variant, cartons with dimensions up to 150 x 110 x 200 mm can be filled at speeds of up to 300 cartons/min.

The cartoner is perfectly matched to the Mediseal primary packaging in the upstream packaging process. The blisters are transferred directly to the cartoner. Stacking is highly accurate, via a Delta robot that is operated from the Mediseal machine control system with the latest simulation technology and by means of cam discs. In this way, the advantages of robotics are exploited without additional robot control systems.

For reliable carton separation when the carton blanks are fed in, Mediseal relies on the patented solution already been applied in the P3200 cartoner. If required, carton loading can also be handled automatically.

The modular construction of the entire unit means that subsequent adjustment to changed product requirements is possible at any time.