Bosch Packaging Technology will offer an innovative system for the continuous production of solid pharmaceuticals with the new Xelum platform that combines dosing, mixing, granulating and pressing. All of these steps are fully automated and proceed without any interruptions, paving the way for more efficient tablet manufacturing.

Along with Xelum, Bosch Packaging Technology will showcase the following at interpack 2017:

Customized services for all maintenance strategies

To enhance machine efficiency and productivity, Bosch is focused on solutions for preventive maintenance as well as services to eliminate unwanted machine conditions as quickly as possible. To this end, Bosch provides a worldwide service network with qualified field service technicians who offer regional support. Thanks to digital services such as Remote Service, which is now supported by a visualization and chat feature, or the mobile version of the E-Portal, to be presented at interpack 2017, customers receive targeted support regardless of their location.

Bosch will also showcase the versatile training portfolio of the Bosch Packaging Academy. Apart from new assistance solutions, Bosch demonstrates virtual training concepts enabling manufacturers to acquire demand-oriented know-how for machine operation and maintenance.

Complete packaging solutions with Track & Trace

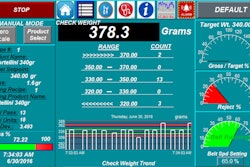

Bosch’s secondary packaging portfolio includes a broad range of cartoning machines, including the horizontal cartoning machine CUT 1405, which offers flexibility in the choice of feeding systems, formats and closure variants. A CPS module with checkweigher and Tamper Evident labeling function serializes the folded cartons. When combined with industry 4.0 technologies such as Bosch’s CPI software, customers receive a complete serialization solution that not only supports all current guidelines, but also provides multi-level connection with the company IT.

Tablet pressing and capsule

The first TPR 500 tablet press “made in Germany” will premiere at interpack. “By transferring production from England to Waiblingen, we have further expanded our Waiblingen facilities’ portfolio,” says Christian Treitel, Head of Pharma Business Development at Bosch Packaging Technology. Equipped with a 56-station rotor, the TPR 500 has an output rate of over 400,000 tablets per hour.

From the capsule filling portfolio, Bosch presents the GKF 2600 with integrated weighing station. The system can process various products like powders, pellets or liquids at output rates of up to 2,600 capsules per minute. The integrated Net Weight Detection System (NWDS) automatically corrects deviations in the filling volume for micro dosing and pellet filling. In addition, the filling process is 100 percent controlled, ensuring precise filling results without product loss.

Comprehensive laboratory expertise

As an example of its broad portfolio from small-batch development to production scale-up, Bosch will present the Solidlab 2 fluid-bed and drum-coater module. The company seeks not only to provide customers with individual machines for research and development, but also offer the support of formulation and processing experts and a wide range of training seminars to help them implement their ideas for new products. In addition, the latest automation solutions facilitate formulation, quality control and data handling. The new phase-testing device, for instance, makes it possible to automatically determine the stability of liquid, creamy or pasty formulations.

Bosch Packaging Technology is exhibiting the Xelum platform along with its track and trace, service systems and more at this year’s interpack in Dusseldorf, Germany, from May 4-10. Bosch Packaging Technology can be found in hall 6, booth A30-C58.