Recent progress in therapeutic treatment advances make terms such as “disruptive,” “innovative,” and “revolutionary” trite, yet an organic vapor jet printing technology in development at the University of Michigan could simultaneously deliver the following impressive gains:

• Enable patients to take a single daily dose that would include multiple medications, making it easier to adhere to prescribed regimens.

• Impact operations for pharmacists in either a retail or hospital environment via on-site vapor printing of such medications onto a variety of substrates.

• Accelerate drug development for the pharmaceutical industry.

“Pharma companies have libraries of millions of compounds to evaluate, and one of the first tests is solubility,” says Max Shtein, Professor of Materials Science andEngineering at the University of Michigan. “About half of new compounds fail this test and are ruled out. Organic vapor jet printing could make some of them more soluble, putting them back into the pipeline.”

This dose-printing technique was developed through a collaboration between the University of Michigan’s departments of chemical engineering and biomedical engineering, the College of Pharmacy and the department of physics in the College of Literature, Science, and the Arts.

According to a UM online article, the technology emanates from an electronics manufacturing process that prints a fine crystalline structure over a large surface area. The process allows printed medications to easily dissolve, “opening the door to a variety of potential new drugs that today are shelved because they don't dissolve well when administered with conventional approaches, including pills and capsules.”

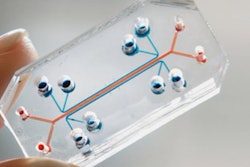

The vapor printing technique can print multiple medications into a single dose on a dissolvable strip, microneedle patch or other dosing device. It is the subject of a study led by Shtein and Olga Shalev, a recent graduate who worked on the project while a doctoral student in the same department. The UM article said the process “showed that the pure printed medication can destroy cultured cancer cells in the lab as effectively as medication delivered by traditional means, which rely on chemical solvents to enable the cells to absorb the medication.”

How it works

UM explains that process begins by heating the active pharmaceutical ingredient (API), typically in powder form, then “evaporating it to combine with a stream of heated, inert gas like nitrogen. The evaporated medication travels, along with the gas, through a nozzle pointed at a cooled surface. The medication then condenses, sticking to the cooled surface in a thin crystalline film. The formation of the film can be tightly controlled by fine-tuning the printing process. The process requires no solvents, no additives and no post-processing.”

“Organic vapor jet printing may be useful for a variety of drug delivery applications for the safe and effective delivery of therapeutic agents to target tissues and organs,” noted Geeta Mehta, the Dow Corning Assistant Professor of Materials Science and Engineering and Biomedical Engineering and a co-author on the paper.

UM admits that printing mass-market drugs is likely years away, yet in the story, Shtein reported, “drug characterization and testing applications may come to fruition more quickly—internally in pharmaceutical companies. One of the major challenges facing pharmaceutical companies is speed to clinical testing in humans. This technology offers up a new approach to accelerate the evaluation of new medicines.”

Healthcare Packaging (HCP) discussed the process with Shtein—focusing on packaging issues—in the following Q&A:

HCP: Is this printing method related to 3D or 4D printing?

Shtein: With our solvent-free organic vapor printing what we printed were coatings of pure APIs. This is accomplished via additive growth of the medication from the vapor phase. Since we can deposit onto any substrate and geometry, the technique can be incorporated in existing 3D or 4D technologies.

HCP: Could this printing be done at a patient’s home on a 3D printer?

Shtein: Yes. But in contrast to an inkjet printer using organic liquid solvents, our process doesn’t require any solvents. The substrate can be a dissolvable sugar strip, transdermal patch or pretty much any medical device you choose, depending on the method of administration.

HCP: What role would FDA or other regulatory agencies play in approving this process for commercial use?

Shtein: In the case of using APIs the process will typically need to go through FDA approvals. This also depends on what type of medicine you print. Some medicines get approved faster than others, and it really depends on the specifics of each medicine, delivery method, available alternatives, upsides vs. downsides for patients, etc.

HCP: Who makes the vapor printing equipment, and can this printing technology work with solid dose, powders and liquid medications?

Shtein: There are several, complementary aspects of the technology we are currently working on. First is further development of the technology toward applications in various medical fields and expansion of capabilities. Second is partnering with equipment manufacturing companies to make the equipment that could better suit the needs of high-volume customers.Yes, within certain parameters, the printing can be done for solid dose, powders and liquid medications.

HCP: What are the safety issues related to using this process with more than one medication? Would the process alter or reduce the effectiveness of each individual medication? Does the process itself (vapor/gas) introduce different properties that could interact with the medication(s)?

Shtein: In terms of safety issues, any process combining several medications will need to go through a set of tests and approvals before it becomes a medicine used by humans. The process itself preserves the chemistry of the API, as was demonstrated in our paper.

HCP: How would these printed strips or other delivery vehicles actually be packaged to get to a patient?

Shtein: The packaging will depend on a route of administration.If the printing is to be performed at the point of care and the medication is utilized almost immediately, there might not be a need for any packaging. In this case packaging would be required for the medication cartridges only.If the printing is to be performed in a manufacturing facility and is further distributed, the packaging would be similar to existing medication packaging for storage under defined environmental conditions, depending if it’s in a film form or another drug delivery vehicle form. Although, we should keep in mind that our direct, solvent-free printing approach opens the door to radically novel packaging options.

Looking ahead, the UM report noted that additional applications for the technology are under exploration, with “plans to collaborate with experts in pharmaceutical compound design and manufacturing, as well as those working on treatments. Eventually, they envision vapor jet printing being scaled to mass production, including roll-to-roll continuous manufacturing.” Watch a video of the process here.