In the world of pharmaceutical packaging, the implementation of the Drug Supply Chain Security Act (DSCSA) has become a focal point for industry professionals. Aladin Alkhawam, a seasoned expert with a career spanning various roles in pharmaceutical packaging operations, offers a unique perspective on the challenges and intricacies of this regulatory landscape. Alkhawam, who now runs his own consulting service, has dedicated recent years to focusing on the DSCSA regulation, which is set to take full effect soon.

HCP: How did you get into the industry… Did you always know you wanted to work in pharma?

Alkhawam: Interestingly enough, not at all. My focus when I went to college was actually electrical engineering—that’s what I wanted to do. But I met someone who worked at a pharmaceutical company and was leaving his role. I jokingly said I might apply for his job, and he encouraged me to do so. He was in the planning department, and sure enough, I applied and got the job as a planner. From there, I moved into the packaging department—all while still in college and not yet graduated. I really enjoyed the fast-paced environment, working with people, and the operational side of packaging. That led me to switch gears—I completed a two-year associate degree in electrical engineering, then shifted to business management. I’ve been in pharmaceutical and packaging since then, which has been my entire career.

HCP: In early days, did you focus on package development or were you always more on the serialization/ traceability/ regulation side of things?

Alkhawam: I initially started my career in packaging, specifically focusing on operations within the packaging department. While I supported the development of new packaging for products and delivery systems, my primary responsibilities were centered around packaging operations. This included implementing new packaging lines, overseeing packaging expansions, and ensuring smooth execution of operational projects.

HCP: And now you're focusing on DSCSA, which is a huge topic with a lot of moving pieces. Maybe you could share a status update of what's going on there.

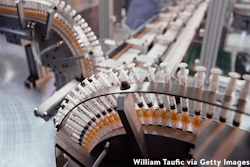

Alkhawam: Sure. The DSCSA requirements were signed into law in 2013 by President Obama, giving the pharmaceutical industry about ten years to implement them. There were a few deadline extensions along the way—one due to COVID, and another because many manufacturers weren't ready. Implementation was phased: first came serialization, which involves placing a serial number on each product; then aggregation, which creates the parent-child relationship between items like bottles, cases, and pallets; and finally, end-to-end traceability, which involves sending associated data to wholesalers.

As of now, manufacturers had until May 27, 2025 to comply, meaning that all prescription drugs must serialize and aggregate, serialization data sent to customers using EPCIS files with their products. Wholesalers have until August 27 to comply. Dispensers have until November 27, 2025, while smaller dispensers with fewer employees have until November 27, 2026. It’s a complex process involving significant systems integration, which is why the industry needed time and resources to fully comply.

HCP: I know there's multiple groups of people, like you said, facing different deadlines and facing different obstacles. But if we focus on the manufacturer, what are some of their obstacles at this point?

Alkhawam: One major challenge is system integration. Multiple systems—used by manufacturers, wholesalers, dispensers, and other trading partners—must communicate seamlessly. Any failure in these connections can halt the entire process. Establishing and validating electronic connections between all parties is both complex and demanding.

Another challenge is developing standard operating procedures (SOPs). Since this is new for many, SOPs are often being created on the fly as issues arise. Sometimes unforeseen problems require companies to go back to the drawing board and revise procedures.

Additionally, the FDA has granted certain exceptions for manufacturers unable to meet specific requirements. However, these exceptions are complex and must be carefully reviewed to ensure compliance. Communicating these exceptions across all trading partners adds another layer of difficulty for the industry.

HCP: I hear a lot about exceptions, and sometimes it seems like it's due to the size of the company, maybe if they're smaller, they have a little bit more time. Does it have to do with anything else other than company size?

Alkhawam: It's not just the company size, it could be systems related. It could be if a product, for example, does not meet the requirement because of a certain circumstances, that may result in drug shortage in the market, that could qualify for exception/waiver as well. But the important thing is that you have to file for that waiver for that exception. You have to file for it, you have to get it approved, and then you have to communicate that with your trading partners.

HCP: Do these manufacturers generally have a staff of people that are as knowledgeable as you on this whole process? Or do they have a team in place to try to figure out how to fully comply?

Alkhawam: Understanding the DSCSA is definitely complex. There are many intricacies involved, and most—if not all—manufacturers, customers, and wholesalers have built dedicated systems and teams to support these requirements. Companies have invested significant resources to ensure compliance, and for good reason: failure to comply could mean patients don’t receive their necessary medications.

That’s why it's critical for companies to be properly staffed and structured to handle all aspects of DSCSA compliance. Both manufacturers and their trading partners—whether distributors, customers, or dispensers—must work together to manage these responsibilities effectively.

HCP: Do you have any tips for implementing DSCSA for manufacturers or anyone else along the value chain… any tips to make the process a little smoother?

Alkhawam: Yes, it’s definitely a team effort. This isn’t something one or two people can manage—it requires cross-functional collaboration. IT, manufacturing operations, customer service, quality, and even finance all play a role. Implementing these requirements demands both system integration and significant investment, so financial support is essential. It’s also important to ensure compliance with GS1 standards. If everyone follows the same standards, it simplifies integration and helps systems work more efficiently together.

Aggregation is another critical aspect—making sure systems are properly integrated and can communicate effectively. Compliance with HDA standards is just as important, particularly regarding label quality, 2D barcode placement, and print clarity. These standards, supported by wholesalers, help ensure that shipments are received and processed smoothly. Accurate validation and thorough testing of these systems are key steps toward maintaining compliance.

Proper aggregation—from unit to shipper and shipper to pallet—greatly improves wholesaler efficiency. Close collaboration with trading partners is essential, whether you're using 3PLs or your own distribution centers. Before going live, thorough onboarding and end-to-end testing with partners ensures that serialization data is transmitted correctly and that all parties confirm they are receiving what they need.

Training is absolutely critical. In my own experience, our teams were involved from the start—in equipment rollout, FAT testing, installation, and final testing. Everyone from line operators to supervisors participated, and that made a huge difference. When production started, the entire floor was already familiar with the process. This shift represented a major change in pharmaceutical packaging operations, and involving the team from day one was key to a successful transition.

Lastly, don’t underestimate the importance of SOPs and documentation. Procedures must reflect actual work being done and be followed closely. Solid documentation ensures consistency and compliance, and helps teams navigate this complex process effectively.

HCP: So, kind of switching gears away from the DSCSA for a bit. Looking back at your career over the last 20 years or so, what have you seen change the most over that time?

Alkhawam: Well, the DSCSA has been one of the biggest shifts in the industry—serialization alone took over a decade to implement. Putting that aside, I’ve noticed other major changes, even though I’ve been away from the packaging floor for a few years. I still stay current by attending industry events like PACK EXPO and pharmaceutical manufacturing trade shows and webinars.

One of the most significant trends is the rise of automation. The workforce is evolving, and younger generations are less inclined to take on repetitive, manual tasks on packaging lines. As a result, we’re seeing more automation, AI integration, and digital data systems being built directly into packaging machinery. Remote troubleshooting capabilities have become especially valuable—what once required an on-site technician can now often be handled remotely, saving time and resources.

There’s also been a noticeable shift toward patient-centric packaging. Where bulk packaging—like large-count bottles—was once the norm, blister packaging is now gaining traction for its usability and dosing convenience. This trend supports better patient compliance and aligns with broader healthcare goals.

Lastly, environmental responsibility has taken center stage. Sustainable and eco-friendly packaging materials are no longer optional—they’re becoming essential to meet evolving regulatory and consumer expectations. This focus on sustainability is much more prominent now than it was in the past.

HCP: I have noticed those trends emerge too... out of the ones you mentioned, any of those seem the most surprising?

Alkhawam: I think digitization and digital manufacturing. Many companies are now shifting toward data-driven operations—closely monitoring metrics like OEE (Overall Equipment Effectiveness) to track efficiencies and reduce downtime. There’s also a growing push toward digital batch records and electronic logbooks, which streamline documentation and compliance. I'm seeing strong demand for these digital solutions, with pharma companies increasingly adopting AI, automation, and integrated systems. This shift to digital is clearly becoming a key part of modern pharmaceutical manufacturing.