COVID-19 has been referred to as a black swan event–an unpredictable occurrence beyond the expected and with potentially severe consequences. These occurrences are characterized by their severe impact and extreme rarity. To be certain, the pandemic has disrupted global supply chains on an unprecedented scale.

The Inner Loop quotes a Harvard Business Review article which says, “The supply shock that started in China in February and the demand shock that followed as the global economy shut down exposed vulnerabilities in the production strategies and supply chains of firms just about everywhere.” According to reports, over 90 percent of Fortune 1000 companies have tier 2 suppliers in the regions of China that were most affected by the initial phase of the global COVID-19 pandemic.

Photo Courtesy: Nimbelink

Photo Courtesy: Nimbelink

Black swan events pierce barriers to adoption

The Inner Loop article points out that black swan events can play a crucial role in nudging decision-makers toward embracing already available technologies and explained that such was the case with the shipping pallet and forklift, another pair of technologies that only rose to the forefront after a previous black swan event–the outbreak of World War 2. While forklift and pallet usage had already been refined in the 1930s, it was only the outbreak of war in the 1940s with ensuing staffing shortages and urgency for material handling efficiencies that the dire consequences of not adopting new technologies became glaringly obvious. With that recognition, the pendulum finally swung toward widespread adoption.

In 2020, the COVID-19 event is now proving to be a powerful motivator as well. The acceptance of already available technologies such as IoT-enabled reusable packaging systems is meant to provide the supply chain visibility needed in resilient supply chains. According to one industry insider, the COVID-19 pandemic has accelerated the digital transformation by 16 to 18 months.

Photo Courtesy: iGPS

Photo Courtesy: iGPS

In its COVID-19 and shattered supply chains white paper, IBM observes, “COVID-19 has driven home the need to strengthen global supply chain networks. Supply chains should be dynamic, responsive, and interconnected to an organization’s ecosystem and processes. This requires end-to-end visibility, real-time insights, and decisive actions—particularly in escalating situations.”

While the range of tracking technologies available can seem daunting, vendors note that quick adoption does not require supply chain participants to have a deep understanding of the various options – only a recognition of their pain points.

The article then dives into some of the challenges arising from COVID-19 and how technology-enabled reusables can make a difference:

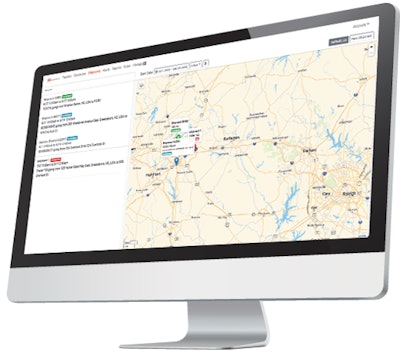

Photo Courtesy: Logistimatics

Photo Courtesy: Logistimatics

Tracking Reusables in Automotive

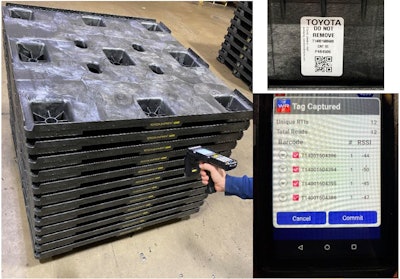

In the spring of 2020, the automotive industry found itself facing plant closures, fractured supply chains, and, in some cases, rapid retooling to produce medical equipment. And as more employees have been assigned to work from home, OEMs have been more greatly challenged to provide the typical oversight of materials.

The flows of containers between tier suppliers and assembly plants have also been significantly disrupted, resulting in increased volumes of lost or otherwise unavailable reusables, according to the article. In the absence of the required reusable packaging, suppliers are forced to use costly expendable packaging.

Such emergency measures are costly, and according to one Reusable Packaging Association (RPA) member blog, “have fueled a renewed emphasis on container tracking in recent months.” While the use of GPS and IoT-enabled reusables has already been established in automotive, vendors stress that it has never been easier to deploy. System providers offer devices, cloud-based tracking systems, and simple user interfaces that deliver immediate insights without the need to integrate with existing IT.

Photo Courtesy: ORBIS

Photo Courtesy: ORBIS

In the recent RPA panel session, Smart Packaging through a Reusable System, Kevin Davidson of Logistimatics noted that powerful insights can be derived from GPS tagging even a small percentage of containers, enabling stakeholders to identify bottlenecks and sources of loss. Through geofencing, for example, exception reports can identify reusables that travel outside of their expected location.

Davidson made the case that the value of a healthy supply chain made possible by GPS and IoT-enabled reusables is a more compelling business case than the avoidance of container loss. “Any time you have to hit that button that stops the line, that’s costing tens of 1000s of dollars every minute,” he says.

Food and Beverage

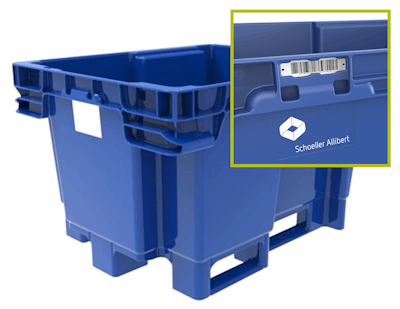

COVID-19 presented challenges that also required a nimble response from the food and beverage industry. Supermarket and e-commerce sectors felt strong demand while the restaurant trade was decimated. Heightened concerns about pallet and container hygiene also surfaced during the early days of the pandemic.

Photo Courtesy: Schoeller Allibert

Photo Courtesy: Schoeller Allibert

The combination of heavy volume and an influx of new employees, including new delivery drivers, has made the accuracy of deliveries and the management of reusables more challenging. Misplaced reusables are more likely to be missorted or forgotten on trailers during unexpected sales surges.

Regarding deliveries, conventional barcode or QR code scanning at the delivery stop does not necessarily mean the product was dropped off at the correct location, Shawn Stockman of Onepak says in the RPA panel. The use of geofence technology in conjunction with IoT-enabled reusables, however, can verify that the correct order is left at the correct location. Technology-enabled systems that minimize interaction between a delivery driver and receiving personnel have become increasingly popular during the pandemic–systems known as “contactless” delivery.

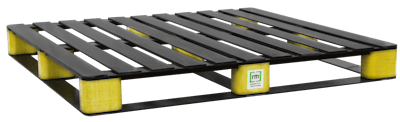

Photo Courtesy: RM2

Photo Courtesy: RM2

The COVID-19 pandemic has also heightened interest in the cleanliness of contact surfaces, including reusable packaging. As a result, many outlets temporarily banned reusable shopping bags. Easy-to-wash reusable packaging, however, provides a hygienic system. As Kevin Mazula of RM2 says in the RPA panel discussion, smart, unique ID reusables can capture their use history, including individual wash events, providing confidence that a particular container is clean for the intended purpose.

Photo Courtesy: Georg Utz

Photo Courtesy: Georg Utz

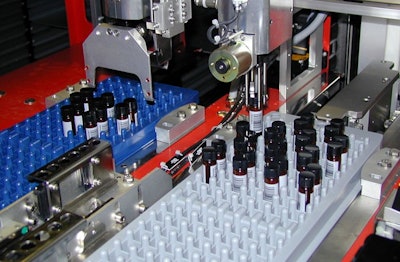

Smart Reusables and COVID-19 Vaccine Distribution

The distribution of COVID-19 vaccines marks an unprecedented supply chain event for the widespread distribution of extremely expensive and temperature-sensitive pharmaceuticals. The temperature requirements are daunting. The Pfizer vaccine needs to be kept at minus 70 degrees Celsius, for example, which is colder than winter in Antarctica. The Moderna vaccine needs to be frozen too, but only at minus 20 Celsius, more like a regular freezer.

Photo Courtesy: Logistimatics

Photo Courtesy: Logistimatics