SC Johnson is taking its refill ambitions to the Canadian mainstream. The maker of Method and Mrs. Meyer’s Clean Day soaps has partnered with London Drugs to pilot in-store refill stations at the retail chain’s new concept store in Burnaby, British Columbia. The move builds on SC Johnson’s years of experimentation with refill systems in Europe and is the company’s first North American pilot of its newest technology.

London Drugs features the refill stations prominently in its 20,000-sq-ft flagship store at The Amazing Brentwood shopping mall. The retailer’s new open-concept, consumer-centered store prioritizes wellness and sustainability and gives shoppers access to expanded pharmacy services, product and packaging recycling, and sustainable product choices. The SC Johnson partnership puts refill packaging at the heart of this environment to encourage reuse as part of everyday shopping.

According to an SC Johnson spokesperson, the inclusion of the refill station in London Drugs’ concept store was a team effort. “London Drugs set out to test a new store concept with a focus on sustainability, and we’ve been working to offer more refill and reuse options for our products to promote reuse/refill systems,” they say. “We worked together to ensure a refill station was part of that store planning process.”

Lessons from the ‘Refillution’

The Burnaby pilot builds on SC Johnson’s earlier work with its Ecover environmentally friendly household cleaner brand in Europe. Ecover’s “Refillution” initiative was launched in the U.K. in 2019 and has now grown to include more than 700 refill stations across Europe. The campaign framed reuse in simple terms, asking, “Why melt a bottle to make a bottle, when you’ve already got a bottle?” The phrasing resonated with shoppers by presenting refill as practical and rewarding rather than a sacrifice.

To share learnings from the initiative, Ecover commissioned a consumer insight report, “The Refillution Has Begun,” that identified drivers and barriers to refill adoption. The report called out three misconceptions—packaging is disposable, recycling is the only answer, and convenience is everything—that must shift for reuse to scale.

It also laid out strategies for motivating consumers, such as highlighting the disadvantages of single-use, creating visible refill movements, and offering cost savings. Equally important were recommendations for removing barriers, including designing systems that minimize consumer effort, ensuring clear instructions, building machines that are failsafe, and reducing refill premiums.

Shaping the London Drugs pilot

Insights from Ecover’s Refillution program guided how SC Johnson and London Drugs designed the Burnaby pilot. One lesson was that visibility is critical. In Europe, refill stations performed best when positioned prominently in stores. Reflecting that learning, the stations in London Drugs are located near the front of the concept store to ensure shoppers encounter them as part of their regular routine.

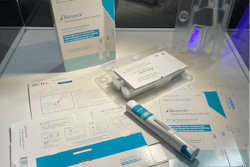

Ecover also found that clear instructions build confidence with first-time users. At London Drugs, step-by-step directions are integrated into the station. The process is straightforward: Consumers purchase a 750-mL Method or Mrs. Meyer’s refill pouch in store, take it home, wash it out once it’s empty, and return to the store to refill it with product again. The packaging is leak-resistant, collapsible for transport, and designed to withstand multiple cycles.

“This refill system is easy to use, quick, effective, and cost-saving and ultimately allows individuals an opportunity to reduce their plastic footprint,” says the spokesperson.

Technology was another area requiring improvement. According to the SC Johnson spokesperson, many early in-store refill systems resulted in product leakage, which drove the need for increased in-store associate time. The London Drug stations incorporate automatic shutoff features to prevent spills and streamline operation. “The latest technology, like what’s seen in the London Drugs store, helps solve for that key issue of spillage and allows for store labor levels comparable or lower than with single-use products,” they say.

Management of the refill stations is a “collaborative effort,” says the spokesperson. “We supply the bulk product for the refill machines, and London Drugs manages the day-to-day operations of refilling the machines when needed,” they explain.

Ecover’s experience also showed that mainstreaming refill requires well-known brands, not niche options. The London Drugs pilot therefore features Method dish soap in Lime + Sea Salt and Clementine scents, Method gel hand soap in Sweet Water and Sea Minerals varieties, and Mrs. Meyer’s dish and hand soap in Lavender and Lemon Verbena scents.

“These are high-impact usage categories that shoppers buy frequently, offering a large circularity impact,” the spokesperson said. “Consumer trust and perception of brands is certainly important, as is market penetration and sustainability attributes of those brands and products. Those were all key considerations in choosing Mrs. Meyer’s and Method brands for this pilot.”

Finally, the Refillution highlighted the importance of economics. Shoppers were more likely to adopt refill when it offered a tangible savings. At London Drugs, the refill price per milliliter is 10% lower than the single-use equivalent, an incentive designed to encourage trial.

Together, these strategies reflect SC Johnson’s broader goals around refillable packaging: making refill systems visible, practical, and affordable in order to shift consumer behavior toward reuse on a larger scale.

Alignment with sustainability strategy

The London Drugs pilot fits into SC Johnson’s larger sustainability roadmap. Since 2018, the company has reduced its use of virgin plastic by 33% through PCR, lightweighting, and refill initiatives. “We plan to offer shoppers a variety of refill and reuse options across our brands in all regions of the world,” the spokesperson says. “These offerings include bulk refills, concentrates, refill machines and reusable storage options. Having a variety of refill format offerings gives us the best opportunity to shift consumer behavior to refill options.”

SC Johnson also sees refill as a component of Extended Producer Responsibility. “We’re encouraged by recent legislation in France, and subsequently Europe, that requires stores to carry refill options,” the spokesperson reports. “In recent U.S. State EPR legislation, we also see the requirements for refill sales, which is encouraging. With legislated requirements, we expect broader adoption of the refill format by consumers.”

Looking ahead

Early adoption of the refill station—which debuted with the opening of the London Drugs flagship store in May—is encouraging, with strong unit velocities, says the SC Johnson spokesperson. “However, it’s still early in the pilot,” they add. “Our hope is that more consumers adapt to this model so that we can continue to look where else we can bring this type of refill and reuse offering.”

The Burnaby pilot may be a limited initiative, but it’s one that SC Johnson views as part of a larger shift. “Every little bit counts to help reduce plastic usage and potential waste,” the spokesperson says. “This is one small step to tackle a global problem.” PW