Mail-order pharmacy, Aponeo, Berlin, Germany, provides patients throughout the country with prescription and non-prescription medications, dietary supplements, contact lenses, cosmetics, and wellness products.

Since 2006, the company’s customer base has grown from 40,000 to 850,000, handling more than 140,000 SKUs, and shipping 4,000 packages each day containing over 20,000 items. To handle this exponential growth, Aponeo last February automated its distribution process for the checking and sorting of batch units by putting into place the SSI Order Verifier from Schaefer Systems International.

“Besides being price-driven, our clients want a large product assortment and fast delivery,” says Patrick Luig, Technical Director at Aponeo.

“It is virtually impossible to carry all products on-site, so we order our slow-movers and medium-movers on demand from our wholesalers,” he continues. “We get about 80 percent of our orders from wholesalers on demand. We then integrate these with our fast-moving SKUs that we keep in inventory to make-up our customer orders. This process of integrating items, and still guarantee next-day delivery and even same-day delivery in Berlin, has been a challenge for us that we were only able to solve with the Order Verifier system.”

How the process works

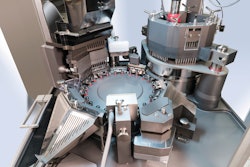

Aponeo’s Order Verifier system is streamlined. At an ergonomic infeed workstation, workers manually empty totes received from the wholesalers onto a V-shaped conveyor. The speed of the conveyor allows for product separation, and once the articles have been separated, each individual item is scanned from all sides and photo-documented. The articles are then automatically directed to one of 12 sorter slots with order-specific totes below.

Workers then place these pre-sorted batch totes onto an automated trolley that takes them to the picking area where the inventoried fast-movers are integrated into the tote-batched orders. Then workers pack the patient-ready orders for shipping to customers.

Before the SSI Order Verifier, every article was scanned manually, which took 2 to 3 seconds per item. Now, Aponeo is running at 0.8 seconds per item.

“The Order Verifier checking and sortation solution cut our leadtime by 50 percent, and our orders are virtually 100-percent error-free,” says Luig. “And we are only running at 50-percent capacity.The whole system is compact, occupying only 500 square-feet within our distribution center. Additionally, since our system can now scan 1D and 2D data-matrix codes, we are totally set up to be compliant with the upcoming industry documentation and verification regulations.”

Helps meet U.S. regulatory requirements

Meanwhile, in the U.S., the Drug Supply Chain Security Act, enacted in Nov. 2013, is transforming how the domestic supply chain operates. The FDA regulations are designed to ensure product safety and stringent supply chain track-and-trace requirements.

This places greater requirements for real-time data capture of SKU lot codes, and soon, full serialization traceability of product movement across the entire supply chain. These new mandates for the distribution of pharmaceutical products will require high-speed camera-based scanning, integrated with automated labeling to efficiently track and trace the shipments.

To help manage these requirements, the SSI Order Verifier identifies, counts, verifies, photographs, and documents products of an order in one integrated process. The system provides pharmaceutical wholesalers with an efficient system to meet the legal track-and-trace requirements regarding documentation of shipped products, including batch tracing, proving the origin of the shipped goods.

“The bulk of pharmaceutical orders, both prescription and over-the-counter products, are packed in small quantities and delivered for individual drug stores, hospitals, and healthcare centers,” says Ross Halket, Executive Director of ASD Sales for SSI Schaefer. “With a throughput of up to 6,000 items per hour and simultaneous photographic documentation, the SSI Order Verifier presents a cost-efficient, automated order verification solution to handle these split-case orders.”

Key functions of the SSI Order Verifier include the following:

• Tote induction. The order totes are automatically uploaded by a tilt device. The system will accept to up to 300 totes per hour;

• Cubic-shaped products. Handles cubic products up to a weight of 2.2 lb;

• Throughput and products singulation. Up to 6,000 items/hr using variable-speed conveyors;

• Product counting and item identification. 1D bar codes and/or 2D data-matrix codes, and RFID readout with a six-side scan;

• Photographic documentation. Each item is photographed to verify having been shipped.

• Order reconciliation. Automated reconciliation of items for customer orders before shipping;

• Error correction. Any “no-read” products are separated to reduce the manual check times. For example, only wrong products require checking; no need to manually rescan the entire order to define the bad reads.

Although the SSI Order Verifier is particularly adapted for the track and trace of pharmaceutical products, it can easily be adapted for use with other cubic-shaped product types.

—This article is contributed by Robyn Schmitt, who writes about advances in fulfillment automation.