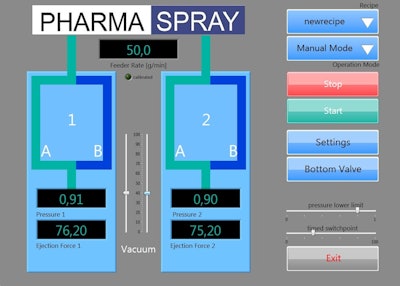

Pharma Technology Inc. (PTI) has introduced two new tableting technologies to the U.S. market. PharmaSpray is PTI’s external tablet lubrication system that sprays dry lubricant continuously onto tablet press punch tips and die walls, delivering a consistent amount of dry lubricant onto the tablet over time. Excess lubricant is eliminated by vacuum suction on the side of the spray nozzle, and then collected in a double bag discharge system. PharmaSpray works well with a wide range of tablet presses used by the pharmaceutical and nutraceutical industries.

Another recent enhancement is the AIO—All In One Tablet Deduster, Metal Detector, and Tester System. The AIO system builds upon Pharma Technology Inc.’s signature PharmaFlex family of dedusters by offering turnkey peripheral devices as integrated solutions. The AIO’s upgraded automated tester, which connects to the deduster/metal detector base without use of cables, tests sample tablets online for weight, thickness, diameter, and hardness. Sample tablets are transferred from the press chute by vacuum (as opposed to Venturi) to help keep the measurement instrumentation dust-free. The AIO tester comes with tool-free dismantling of all product contact parts for easy cleaning, as well as dust-tight segregation of technical areas. The result is streamlined performance that directly monitors and controls the manufacturing process with significantly less operator supervision.

PTI has also introduced the PTGV 1200 Capsule Polisher. The PTGV 1200 combines on a single base an elevating hard-gelatin capsule polisher with a metal detector and empty capsule eliminator. A vertical rotary brush cleans residual powder or dust at the seam of capsules. Its compact footprint and mobility (only one cable is required to power all three elements) allow the PTGV 1200 to fit in tight production rooms. All product contact parts can be dismantled without the use of tools.