A transparent, cellulose-based film made from wood pulp, a renewable resource, is the clear choice for wrapping organic products made by soap maker Tikvah, and brownie maker Raw Indulgence (see sidebar, p. 60). The biodegradable, compostable film, called NatureFlex™, is supplied by Surface Specialties UCB.

By using specially formulated coatings, Surface Specialties UCB can change NatureFlex’s moisture transmission and barrier properties. That’s the case for Tikvah and Raw Indulgence. To keep its brownies moist, Raw Indulgence opts for a stronger moisture barrier than Tikvah, whose soaps benefit from a more permeable film.

Tikvah is a Hebrew word meaning hope. It’s also the name of the Petaluma, CA, home-based business run by Cyndi Norman that produces organic soaps. Tikvah is now expanding thanks in part to the NatureFlex film.

“We’re dedicated to organic products,” notes Norman, who is extremely sensitive to chemicals. “We don’t want to use anything in our products or packaging that can have a negative effect on the environment.”

She says, “Before I began using the film this year, we wrapped soap bars in organic cotton paper. The problem was that the company that supplied the paper stopped making it in the [limited] amounts that I needed. And you couldn’t see through the cotton. I wanted something transparent. We like that our customers can see our products inside the package, yet the soap is protected from dust, handling, and contaminants.”

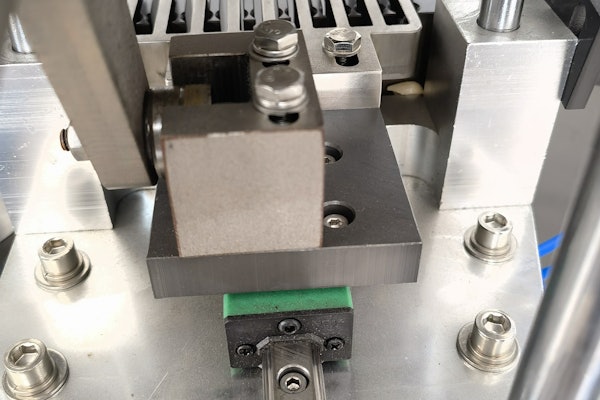

Manual wrapping “was labor-intensive,” she adds. “And it took a few extra seconds per bar to properly fold the cotton paper and then tape it. When you’re paying somebody $12 to $15 an hour to do that, it starts to eat into your profits.” Tikvah heat seals the NatureFlex-wrapped bars on a Midwest Pacific-brand semi-automatic machine from J.J. Elemer.

Norman says she learned of NatureFlex at last year’s All Things Organic show in Austin, TX. She requested information about the film and Surface Specialties UCB responded with details.

The film supplied directly to Tikvah incorporates specially formulated biodegradable and compostable surface layers to control the film’s moisture permeability. Those proprietary heat-sealed surface layers form the two exterior layers of the substrate. Inside each of those two layers is a thin tie layer. The tie layers sandwich the film’s transparent cellulose material core. Overall, the transparent 1.2-mil NatureFlex 120 NE38 structure provides a moisture-vapor transmission ratio of 38g/100 sq”/24 hr.

“The film is moisture permeable,” says Norman. “I wanted that specifically. With most products, like food, you don’t want moisture going back and forth through the package. With soap, the older it is, the better it gets because as the water slowly evaporates, it becomes harder, lathers better, lasts longer, and is just a much nicer bar. So I chose the NatureFlex film variety with moisture permeability.” There is little, if any, scent to the soaps.

Tikvah uses 71¼2”-square sheets of NatureFlex, but expects to change to bags in the near future. Bags would only need to be sealed on one end, requiring less labor. “We’ll still need to apply a label to the top of the bag, but we’ll be able to automate the sealing,” she says.

Tikvah employees apply a pressure-sensitive paper label to the top of the film. “I wasn’t able to find anything organic,” Norman says of the label, though she is more than satisfied with label supplier Labels Now. Supplied to Tikvah in rolls, the paper labels have a gold veneer finish. Flexo-printed in black, the label copy includes the Tikvah name, soap variety, and ingredients, followed by a sentence that reads, “Wrapped in biodegradable cellophane.”

Asked to compare costs between NatureFlex and the former wrap, Norman says, “The cotton paper was a little more expensive, but neither material is that expensive, with costs between two and five cents per bar. When you’re selling for about $6 per bar, it’s not that big a deal.”

NatureFlex is now used for three varieties of hand-cut bar soaps whose average weight is 5 oz, though Tikvah does not put any specific weight on the package of the hand-cut soaps. These are sold for $5.75 to $6.50, mainly in the Oakland, CA, market. The wrap is also used for small, triangular-shaped soap pieces for bed-and-breakfast, spa, and hotel sales. Norman also markets them on the company’s Web site www.tikvah.com.

She points out that Tikvah is in the process of expanding its sales. “Surface Specialties UCB has been really good working with me and sending me a much smaller amount than its minimum order.” In the future, Norman expects to move to a rural property with a barn that will be renovated. “When that’s done, we’ll hopefully be able to do 5 or 10 times as many packages.”

For now, Norman says, “Customers really seem to like the packaging. They can see the product. They pick it up and look at it. Before, with the paper, they’d kind of open up the ends and look at the soap. I wanted them to see the soap and ooh and aah over it, and this film does that. When I tell people who are into organic [goods] that the film isn’t plastic, but a biodegradable cellophane, they are very impressed.”

See the sidebar that goes with this story: Brownie maker indulges in sustainable film