Industry faces many challenges when utilizing complex packaging systems and describing emerging technologies in the field of package integrity testing. Container closure integrity (CCI) failures can lead to significant risks to product quality. Failure of CCI is a critical risk, as a lack of package integrity can lead to product contamination. Contamination of a sterile product intended for parenteral administration can lead to dire consequences for the patient. Stability testing, method sensitivity and reliability, as well as suitability are some of the factors that need to be taken into account to reduce potential risk of contamination to products.

Best practices suggest that all processes be evaluated for risk to product quality attributes, and by extension, to the patient. The general goals of container closure integrity testing (CCIT) are to mitigate the risk through process validation and quality control. Testing for CCI is intended to provide evidence of the use of appropriately matched components and an adequate closing process. Once a product reaches commercial manufacturing, in-process control of critical production and processing steps are necessary.

Container closure integrity tests in conjunction with the control of the overall manufacturing process ensure a high level of CCI. Regardless of the choice of the integrity test method, the chosen method at the particular stage in the lifecycle of the product should be suitable for the intended use and able to reliably and consistently detect a critical leak that can potentially compromise product sterility. Details within USP <1207> serve as the principal guidance, focusing on the basic understanding of package integrity and some of the industry’s current best practices for CCIT.

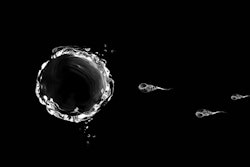

Pharmaceutical container closure systems may have a variety of functions; however, assurance of package integrity is primarily concerned with product containment and the maintenance of an effective barrier against ingress of microorganisms or potentially reactive gases, and, in some instances, the maintenance of a vacuum. Package integrity should ensure product quality is maintained over the shelf and use life. In recent decades, there has been progress in analytical technology to improve capabilities to evaluate closure integrity.

Demonstration of CCI is required throughout the lifecycle of a sterile pharmaceutical product, assuring integrity of the container closure system until its expiration date. A well characterized and controlled process should consist of a qualified container closure design with effective, monitored process controls in place to assure the maintenance of the process parameters required to produce effective container closure systems. A thorough knowledge and understanding of the product-package profile is critical for designing an appropriate package system, as is identifying and understanding the level of risk a measured leak rate poses to the sterility and stability of the product (i.e., identifying the maximum allowable leakage limit large enough to allow for microbial ingress and/or pose a stability risk [changes in oxygen or moisture levels]).

Flexible pharmaceutical containers come with their unique set of challenges with respect to CCI test method validation and leak detection. While there are many methods to test for integrity in these containers, there is no one single test method that fits every situation. The CCI tool kit should encompass different methods that can be employed to detect defect types that are critical to product quality and sterility. Every CCI test method has its advantages and disadvantages; the right choice often requires a tradeoff between them and the requirements to maintain the sterility of the product/package system and ensure highest levels of patient safety.

The 2017 PDA Container Closure, Devices and Delivery Systems: Compatibility and Material Safety Workshop in early October brought together industry leaders and regulators to examine the issues associated with compatibility and safety of drug device and delivery systems. Important topics included the future of drug delivery, strategies for safety evaluation, strategy for thresholds, best practices for extractables and leachables, and compatibility of delivery systems with biologics.