This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

[Editor's Note: The views reflected here are those of the International Hologram Manufacturers Association (IHMA).]

The FDA has issued draft guidance on the Drug Supply Chain Security Act (DSCSA) to help identify and trace drug products in the supply chain. Dr. Paul Dunn, chair of the IHMA considers these and argues that a product identifier initiative by itself cannot be considered an authentication solution under ISO 12931.

Regulation continues to drive concerns for those involved in pharmaceutical manufacturing, production and distribution with governments, national agencies and those with responsibility for law enforcement. This has led the sector to protect itself from criminals and counterfeiters through the DSCSA among other legislation.

While some requirements began in 2014 with other key requirements following in recent years, the new requirements - development of standards and the system for product tracing - will continue to be phased in until 2023 with the FDA committed to working with trading partners and other stakeholders to effectively implement the new requirements.

Since 2017, pharmaceutical manufacturers have been required to print a unique product identification code on all prescription drug units of sale and homogenous cases distributed in the U.S. The move came against the backdrop of continued increases in counterfeiting and the illicit supply or falsification of pharmaceutical products. This in turn continues to have a deep impact on brand values, market capitalization, and supplier reputation.

According to World Health Organisation (WHO), counterfeit drugs are estimated to account for around 10% of all pharmaceutical production. North America is the largest pharmaceutical market in the world and in spite of strict regulatory policies; counterfeit drugs, particularly those available online, continue to pervade the market. Per estimation from WHO in 2012, the loss suffered by pharmaceutical industry for counterfeit drugs was over $75 Bn.

The ground breaking Drug Quality and Security Act came into law under President Obama. Title II of the Act - the Drug Supply Chain Security Act - outlines critical steps to build an electronic, interoperable system to identify and trace certain prescription drugs as they are distributed in the United States. The system is designed to facilitate the exchange of information at the individual package level about where a drug has been in the supply chain and will enable verification of the legitimacy of the drug product identifier down to the package level. It will also enhance detection and notification of illegitimate products in the drug supply chain while facilitating more efficient recalls of drug products.

Drug manufacturers, wholesale drug distributors, re-packagers, and many dispensers (primarily pharmacies) are working in cooperation with the FDA to develop this new system fully over the next few years, with key provisions to be implemented covering requirements for product identification, product tracing, product verification, detection and response, notification, wholesaler licensing, and third-party logistics provider licensing.

Now, the FDA has recently published new guidance documents that provide recommendations for complying with the DSCSA in order to identify and trace drug products as they move through the supply chain. Two final guidance documents and two draft guidance documents were issued. The Product Identifiers Under the Drug Supply Chain Security Act, Q&As clarifies the DSCSA requirement that manufacturers and repackagers add a product identifier on drug packages that includes a national drug code, serial number, lot number, and expiration date, while the Drug Supply Chain Security Act Implementation: Identification of Suspect Product and Notification offers some trading partners aid in identifying a suspect product. It also describes how to notify FDA of illegitimate products.

The Definitions of Suspect Product and Illegitimate Product for Verification Obligation under DSCSA describes terms used to define ‘suspect’ and ‘illegitimate’ products and revises the March 2018 draft guidance, and Enhanced Drug Distribution Security at the Package Level under DSCSA details requirements for enhanced drug distribution security at the package level and provides recommendations on the system attributes necessary for secure tracing of product at the package level.

The development is designed to strengthen the FDA’s hand in helping to protect consumers from exposure to drugs that may be counterfeit, stolen, contaminated, or otherwise harmful, improving the detection and removal of potentially dangerous drugs from the supply chain to protect consumers. Failure to comply with the requirements of the law can result in penalties while the development of the system is phased in with new requirements that will include providing product and transaction information at each sale, in paper or electronic format, and placing unique product identifiers on individual drug packages.

Furthermore, Chapter III: The Identification of Suspect Product and, for manufacturers, product with a high risk of illegitimacy includes a clause – Appearance of the Product – provides guidelines recommending that heightened vigilance is appropriate in the following instance (among others)…Package that is missing security or anti-counterfeiting technologies normally featured on the FDA-approved product that are easily visible to the eye, such as holograms, color shifting inks, neckbands, or watermarks.

Raising standards

Counterfeiting is being driven by many factors: increased industrialization, advanced printing and reproduction technologies, the impact of the internet, vulnerable supply chains, the power of consumerism, ineffectual law enforcement and lenient criminal penalties among others. And while the U.S. will always be in the crosshairs of the counterfeiters, it’s in the new economic powerhouses where the counterfeiting of and illicit traffic in all kinds of pharmaceuticals, medicines, and drugs has become most prevalent and brand sanctity faces some of its biggest threats.

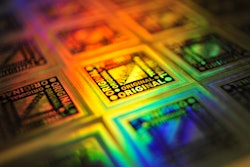

ISO 12931 talks about the ‘Performance criteria for authentication solutions used to combat counterfeiting of material goods…’ - that is, specifying performance criteria and evaluation methodology for authentication solutions, but track and trace technology by itself is not a security solution. However, in conjunction with an optically variable device (OVD) such as a hologram, it can become a potent added value security solution.

The identity of individual items can be linked to packaging through a unique code, which in turn can be linked to case ID, pallet ID, or container ID. The recording of this so-called parent/child relationship between unit pack, carton and pallet is the beginning of an electronic pedigree that allows the item to be tracked and monitored throughout the supply chain: from the production line and packaging through distribution channels to the final end-user. This type of usage can also be used to capture important events in a product’s life cycle – for instance, quality assurance rejects and product returns – creating a flexible database, which offers a unique product history and other business recording benefits.

So why does this matter? The DSQA must be considered highly significant and important legislation, which cannot be ignored. It addresses the supply and distribution of illegal or counterfeit products and impacts on manufacturers, re-packers and wholesalers who must comply with the track and trace, UDI and validation requirements. Moreover, it highlights the importance of using an optical security feature such as a hologram over and above serialization.

The view of the IHMA is that a product identifier initiative by itself cannot be considered an authentication solution under ISO 12931. However, advancements in optical security technology now mean that when it’s integrated with track and trace it can provide manufacturers with the tools to be fully compliant with the legislation; incorporating features that can help users generate unique sequential, encrypted or random serial numbers, or identify and mark products overtly or covertly either via special self-adhesive labels or directly onto pharmaceutical products using a variety of print technologies.

The capacity of holograms to incorporate other data forms and product tracking information will become increasingly important as technology pushes forward and the nature of anti-counterfeiting changes with the times. This enables them to be used for a widening range of pharmaceutical authentication and brand protection roles, linking on-pack product identification with supply chain management, market enforcement and forensic support services. In this way, the identity and distribution of goods can be controlled through a total system solution involving security authentication features, tracking mechanisms and investigative services.

Of notable value to the brand owner (and a strong financial incentive to make the investment in such systems) is the fact that the information generated at the labeling stage can be linked to the company’s ERP (enterprise resource planning) system; enabling business functions such as manufacturing, supply chain management, finance, projects, HR and customer relationship management to be captured and better managed.

Integration

The move towards outsourcing the production of pharmaceutical products not only reduces manufacturing costs but also impacts hugely on the control of brand security and visibility. Here holograms can be integrated into the supply chain security process to allow companies to maintain control of their products: from the sourcing of labels or proprietary components to the manufacturing and shipment of finished goods.

Holograms can also be integrated with secure web interfaces to help eliminate rogue ordering of products while authorized distributors can pick, pack and ship items in carefully measured quantities to customers, with the product’s movements throughout the supply chain, fully tracked and documented. And it is important to encourage the brand owners to take the necessary steps to create awareness about holograms - and their multifarious applications and benefits - to fully unleash their potential.