Gerresheimer, a global partner to the pharma and healthcare industry with products made of glass and plastic, has added laboratory and regulatory services to its portfolio of products, systems, and services for biotech companies. Specialized laboratory technicians and an experienced team of further specialists offer these services in the two innovation and technology centers in Bünde (Germany) and Vineland (New Jersey/USA).

Gx Biological Solutions says it offers full service for biotech companies regarding product development of primary packaging and drug delivery systems, material and functional testing, and comprehensive regulatory support. The partnership with Gerresheimer shortens the time to market for pharmaceutical companies, minimizes risks, and saves resources, says the company.

"Our Glass Innovation and Technology Centers, with their new laboratory and regulatory services, take a lot of the work off our customers on the long road to regulatory approval," says Stefan Verheyden, global vice president of the Gx Biological Solutions Team.

Glass Innovation and Technology Center, Bünde (Germany)

This center is located at the production site for glass syringes, injection vials, and cartridges in Bünde. The range of services includes laboratory and regulatory services by regulatory experts for DMF III (Drug Master File) and the new MDR (Medical Device Regulation). Product support is provided by the relevant product and material experts, who should be able to take care of the correct specification, and guide regarding fill & finish questions.

Chemical analyses are done to help in finding the appropriate packaging system with regard to material in direct contact to the drug formulation, such as glass, tungsten, adhesives, silicone oil, or polymers. Customer-specific developments and design proposals are also developed and adapted to intelligent systems as required. Throughout the whole value chain of drug development, subsequent testing and analyses can be conducted. Material and particle analysis, extractables and leachables testing, container closure integrity investigations, drug container interaction and aging tests, residual volume, fill & finish support, and orienting stability tests are examples of cutting edge services that Gerresheimer will offer.

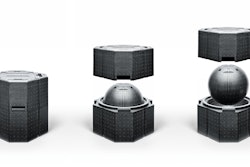

A sample stock will hold many frequently used possible container formats for biopharmaceutical development in order to enable customers to rapidly respond to any urgent market requirements they might face. The Gx innovative portfolio includes strengthened glass vials (both in non-sterile and ready-to-fill format), silicone-free syringes, safety devices–also in already assembled, sterilized, and nested format (Gx RTF)–and other intelligent primary packaging systems.

Glass Innovation and Technology Center, Vineland (NJ/USA)

In parallel Gerresheimer has expanded the reach of the existing Glass Innovation and Technology Center in Vineland (NJ/USA) with a comparable extended service offering as specified for the Bünde site. Next to the existing material science capabilities, functional testing will be added. The company says the development capacities with dedicated lab and regulatory services for primary packaging such as injection vials and cartridges has advantages when it comes to significantly reduced “time to market”.

At Vineland, experts and engineers who specialize in glass technology work in an environment that encourages collaboration through open offices, project, laboratory, and meeting rooms. The environment also enables interactive collaboration with customers on site. The Innovation Center was the first of its kind for Gerresheimer's primary packaging glass business and was built in 2019 next to the plant in Vineland. Thus, the Innovation Center develops and tests new products and processes in close proximity to a production site and can incorporate the operational know-how of engineers from this plant–Gerresheimer's other American production sites can also use the service. It comprises a detailed analysis of the primary packaging material; for example, the material, surfaces and functions of injection vials are tested and chemical analyses are carried out. Gerresheimer also accompanies and supports its customers with regulatory support, official documentation, and registration.