This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

StackTeck leveraged the advantages of hot runner and stack mold frame technology used to achieve high levels of productivity. In response to the urgent demand for medical parts needed in record time, StackTeck delivered a production stack mold with a full hot runner for a face shield headband producing samples within 3½ weeks of the project start.

Vince Travaglini, StackTeck’s CEO stated: “We were challenged by Novolex, to build a class 1 high performance stack mold in just 4 weeks to meet the demand to fight the COVID-19 pandemic. This project included complete mold design, manufactured molding surface components, assembly, and mold qualification. We were able to produce samples molded with customer resin and colorant to final product specification – and we were proud to deliver even faster than requested.”

“StackTeck truly delivered for us in the incredibly short timeframe we required to make the injection molds needed to produce face shields for healthcare and other frontline workers,” said Ken Meyers, Vice President of Operations for WNA, a Novolex company. “We’ve worked with and depended on StackTeck technology for many years and our trust in their know-how was renewed yet again on this emergency project.”

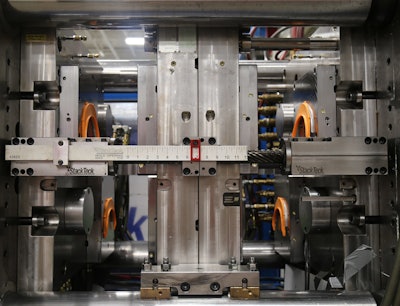

Production stack mold in 2×2 format.

Production stack mold in 2×2 format.

Lou DiMaulo, Sr. Vice President of Manufacturing stated, “We looked at this challenge, and decided to push everything to the limit and get it done. We have a really dedicated team here, and I knew that nobody would back away from getting this done as fast as it could be. Everybody had to get creative and work together to make it happen. In the end, it was very satisfying for the whole team to see the results, and to know we delivered early to a customer who is providing such essential PPE for the people on the front lines.”

Many of the team members who made it happen.

Many of the team members who made it happen.

Video of 2×2 headband mold: https://stackteck.com/about/videos/2×2-headband-mold-for-face-shields/