This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Remote support brings with it challenges such as customer relationships, troubleshooting, new machine startups, and functional tests. These challenges require new strategies to ensure the best response to customer needs. MG2, which designs and manufactures processing and packaging machines for the pharmaceutical, cosmetic, and food industries, has expanded its remote services to help ensure that critical industries remain operational during the COVID-19 crisis.

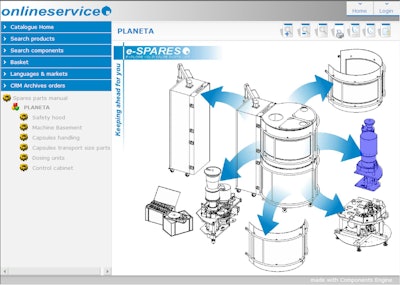

MG2’s Onlineservice platform gives customers the ability to view documentation for a machine and access the spare parts catalog.MG2

MG2’s Onlineservice platform gives customers the ability to view documentation for a machine and access the spare parts catalog.MG2

To solve the difficulties caused by reduced movement of both people and goods during the COVID-19 pandemic, MG2 has activated a new on-site repair service, enabling customers to send machine parts to MG2 headquarters in Pianoro, Italy, where they are repaired and sent back.

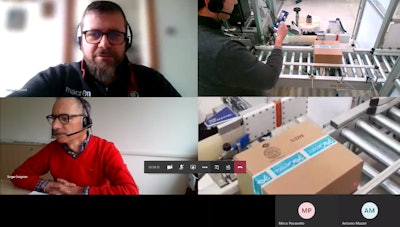

In addition, office automation solutions—including Microsoft Office 365 and the Microsoft Teams videoconferencing tool—enable MG2 to maintain constant relationships with customers, even if it is impossible to reach the company headquarters. Distance, therefore, is not a critical concern for organizing operational meetings, testing machines, and running factory acceptance tests (FATs). MG2 has adopted a wearable technology system based on two video cameras and a smartphone connected to the Internet. MG2 technicians wear this system, providing customers with a live remote user experience as close as possible to on-site tests.

MG2 technicians can integrate live video images and machine operating data, for example, which can be shared during the remote meeting. Filming can include fundamental phases such as special parts operation, size change over, management of rejected capsules, and real-time information on the weight control systems installed on MG2 machines. Images allow the customers to follow the entire intervention, whether that’s testing, maintenance, or repair.

During the COVID-19 emergency, MG2 is fully operational thanks to its commitment to finding innovative and sustainable solutions to keep continuous contact with its partners. New technologies the company is pursuing include neural networks and artificial intelligence, which will be soon applied to MG2 capsule filling machines, aiming to make the machines capable of self-maintenance (both preventive and predictive).