We all know the COVID-19 vaccine was developed in record time, but have you pondered how the manufacturing facilities were built to support mass production and distribution? A recent Fast Company article took a look inside these quick-build factories and shed some light on how they were built concurrently with vaccine development. Typically, this process would take years, but Lonza employed a new method that expedited the process to just months.

How Did COVID Vaccine Plants Get Built So Quickly?

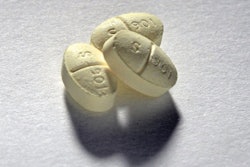

Expedited vaccine development required special planning to ensure mass production capacity.

Jan 28, 2021

Researched List: Blister Machines for Life Sciences

Need a blister machine for life sciences packaging? Our curated list features companies serving pharmaceutical, medical device, nutraceutical, and cosmetic industries. Download to access company names, locations, machine specifications, descriptions, and more.

Download Now

Sustainable Healthcare Packaging Solutions That Work

Industry leaders share proven strategies for reducing packaging emissions by up to 70% while meeting safety and regulatory requirements.

Read More

Downloads