This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

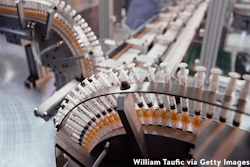

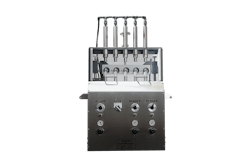

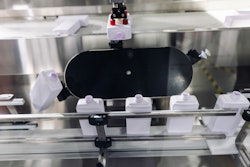

Accutek Packaging Equipment Companies, Inc. announces the launch of the Accutek ACCU-Doser. Designed to meet the growing demand for precision and efficiency in the pharmaceutical, cosmetic, and food industries, this machine streamlines the filling process while maintaining high levels of accuracy and performance. The ACCU-Doser is engineered to fill syringes with liquids, creams, and gels consistently, making it ideal for applications where exact doses and reliability are critical. Featuring an easy-to-use interface, quick changeover capabilities, and enhanced automation, this system can help production lines by reducing downtime and maximizing throughput.

What's New?

Accutek's ACCU-Doser uses technology to deliver faster filling speeds while minimizing product waste. Key benefits include:

- Precision and Accuracy: Advanced metering systems ensure consistent fill volumes with minimal variation.

- Flexible Design: Supports a wide range of syringe sizes, accommodating a variety of industries and applications.

- User-Friendly Interface: Operators can easily monitor and adjust settings for optimal performance.

- Increased Efficiency: Faster cycle times and reduced maintenance needs improve overall productivity.

- Cleanliness: Sanitary delivery makes the filler suitable for handling medical products.

"At Accutek, we understand the challenges that manufacturers face when it comes to filling small volumes," said Darren Chocholek, CEO at Accutek. "With our ACCU-Doser, we're providing an innovative solution that addresses the need for both speed and accuracy, helping companies meet the demands of an ever-evolving market."