This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

APD = Automated Process Development: APD is a Syntegon GKF capsule filler and TPR tablet press machine technology package to improve process parameter optimization, speed up product development, and provide benefits in manufacturing.

APD allows you to gather decision-making data with a lower material and time investment cost. The reduction of R&D resources allows more capacity for experimentation. The optimization in development lowers lifetime manufacturing costs

QbD = Quality by Design is encouraged by the FDA and is a approach to development that begins with predefined objectives and emphasizes product and process understanding.

DoE = Design of Experiment

CPP = Critical Process Parameter = not all the adjustable parameters are critical for any given product, part of the goal of APD is to determine which parameters are critical to achieve your Critical Quality Attribute.

CQA = Critical Quality Attribute = measurable desirable physical and chemical characteristics of a unit dose

CMA = Critical Material Attribute = flow rate, bulk density, etc.

The critical material properties (CMAs) and the critical process parameters (CPPs) interact and influence the critical quality attributes (CQAs) of the tablets or capsules.

APD is one solution to benefit both R&D and manufacturing with a QbD approach, implementing DoE to help identify Critical Process Parameters and understand Critical Material Attributes to achieve our target Quality Attributes.

APD is available for both tablet compression and capsule filling. APD is an available option on a GKF 720 or TPR200+ and it’s also available as a service, from our Customer Service Center in Waiblingen, Germany.

APD for Capsules

A challenging aspect of the capsule-filling process is the variability of powder characteristics and their influence on how machine settings can affect weight and yield.

Automated Process Development, launched in 2020, is a tool that follows a QbD approach to develop optimal process parameters for a new product or optimize an existing product to improve any number of quality attributes. APD can also be used to assist with Product Development.

APD is a Syntegon-adapted software package working in conjunction with specialized hardware on our equipment to measure, and automate to adjust machine settings historically only done so manually.

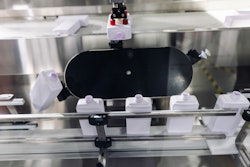

The system requires a Syntegon KKE 100% capsule check weigher in line with a Syntegon GKF 720 capsule filler to measure gross capsule weight and provide this Critical Quality Attribute to our APD Software in real-time.

Regarding formulation development where we still have the formulation as a variable, you have the opportunity to run back-to-back APD machine runs with varying formulations to document their effects on your CQAs. An observation here is that the API percentage has an unexpected influence on weight even though the bulk density matches the excipient.

Possible factors are partial shape and their cohesiveness after tamping.

Capsule Case Study

The power of the system is its ability to execute a large number of tests in a short period of time with minimal product.

The below example is a synthetic drug blend filled into a size 0 capsule at 500mg. A new API was used (particle size has changed) and quality control measures detect little API within the capsules. The target of the APD trial was a segregation study to see how the machine parameters are influencing content uniformity.

In order to execute an APD trial run, a user starts with their existing DoE software, any number of systems are compatible as the .csv file of the feasible design space is downloaded into the APD system.

Under this direction, the APD systematically executes the machine test runs with a product to discover the optimal set points based on your inputted Critical Quality Attributes of the filled capsule. Primarily weight and its standard deviation but as you can see in this example, APD can be used for trouble shooting other CQAs.

We’ve executed 50 tests in 2 hours using 2 kgs of material.

The results of the segregation study (Figure 4) show that contrary to expectations, no API loss occurred during product feed. Instead, the height of the powder bed plays the main role in API loss. It was shown that a low powder bed height leads to lower API losses. An interaction between machine speed and suction setting was also found: more API loss was observed at low machine speed and higher suction setting. Thus, keeping the powder bed height low and running the machine with a higher speed and less suction will avoid the API loss.

The parameters being adjusted are the typical parameters of an intermittent-motion tamping-style capsule filler, i.e. tamping pressure, tamping pin penetration depth and profile, machine speed and powder bed height (by +/- 2mm). While all of these are adjustable by an operator, most of them require manual intervention after stopping the machine and opening the doors. The addition of hardware allows automated adjustment during the machine test runs without a pause in the operation.

Different products react differently to the direction of machine settings. Some products increase in weight with an increase in powder bed height while some decrease.

What we learn from APD is not only the Optimal Process Parameters but also what complex parameter interaction is influencing your Critical Quality Attribute. As in this example, machine speed together with bed height.

You start with your DoE to execute your automated machine experiments to get results that point you to your Optimal Parameters or to help evaluate API and excipients for formulation development.

Other examples would be how little magnesium stearate can we use without stickiness occurring, or how much glidant is needed to create a uniform weight distribution across a batch with a poorly flowing product.

APD for Tablets

APD can be applied to tablet compression in a similar manner to the capsule-filling process.

The user creates the test plan with their DoE software, downloads the .csv file into the tablet press fitted with APD, and the machine automatically adjusts its set-up and parameters to find the optimal material quality attributes and produce a batch of tablets that is as homogeneous as possible.

A tablet press, has potentially more variables as well as more than one quality attribute. With capsules, weight as a sole primary concern.

For tablets, weight and hardness and other CQAs should be considered, such as the release of the drug, the content uniformity, and the disintegration time. The automated commissioning uses an iterative algorithm that calculates the optimal parameter settings considering all CQAs.

For the turret and compression parameters, turret speed, filling depth, and pre and main compression force.

Tableting begins in the powder feeder. The configuration of the feeder has been variable, but to understand how paddle speed, direction, shape, and quantity impact the tablet quality, Syntegon developed an automated feeder.

This feeder, used strictly for this APD application on a TPR 200+, is flexible so it can respond to the APD system inputs as part of the testing execution.

The feeder lets you explore the boundaries of a tablet press variability, including, altering from two paddles to three-paddle configurations with independent control of each paddle for rotational speed, direction, and shape.

Our patented paddles have a square and round side and can rotate 180 degrees. Since the manipulation is fully automated, this allows for a assortment of combinations of independent paddle shapes, speed, and direction in either a two or three-paddle arrangement. There are 26 possible configurations of the powder feeder.

The wrong paddle shape, speed, or direction can lead to poor filling of the die, capping, unwanted shear forces, excessive pre-compaction or aeration, bridging, or over-lubrication and any of these factors can effect on tablet quality.

Automating the feeder configuration and settings reduces the generation of dust and material waste that would accompany the opening and refitting of different paddles or complete alternate feeders.

While the tablet press is running its APD tests, there are two ways to take samples. One is to do so manually when signaled by the press. Alternatively with the use of an inline Pharma Technology CU-120 tablet inspection system.

The CU-120 employs a multipoint NIR-SRS (near-infrared spatially resolved technology) probe to predict API fraction, and a 3D micro-wave resonator allows to measure of the individual weight of a single tablet up to a speed of 120,000 per hour.

Tablet Case Study

In a recent customer-commissioned test, the Syntegon Team in Waiblingen, Germany conducted 47 consecutive APD experiments completing the trial in 52 minutes while using 11 kgs of material in a Syntegon TPR 200+ tablet press fitted with the optional APD system. The goal of the trials was optimization. Two routes were chosen as part of the overall plan. First, the APD trials were run with a focus on maximum output where we had a fixed turret speed of 100RPM. The second set of test runs was done, releasing turret speed to be a variable with a focus on the tablet quality.

It was noted by the customer that APD was able to hit their tablet quality targets with a much lower compression force. Once implemented in high-volume manufacturing, the reduced tooling wear and lower tablet press maintenance costs will have a positive impact.

Application of APD Results - Optimization

The Automated Process Development provides a solution using efficiently planned Design of Experiments in combination with a high level of automation found in the APD-equipped unit operations mentioned here.

This technology, available as an equipment feature or as a service, provides pharmaceutical manufacturers with the ability to determine the ideal process parameters for each product and transfer them to production machines in less time.

Foreseeable benefits include formulation support to improve time to market for new drug products. As well as to conduct studies on changes to raw material suppliers for both APIs and excipients. Furthermore, optimization of new solid dosage forms can speed up transfer to production.