This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

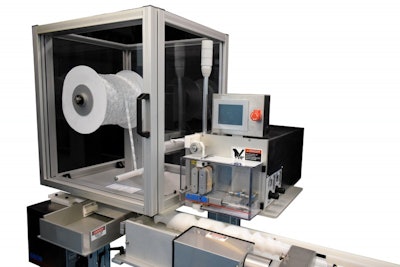

AZCO Corp. has designed and manufactured a pouch dispenser for an application that required dispensing desiccant into bottles at a line speed of 80-90 bottles/min. The unit was designed for controlled environments.

• A roll of the desiccant material is placed on a motorized unwind which controls tension on the web and helps to ensure high accuracy and consistency.

• From the unwind the material is guided into the cantilever dual servo drive belts and self-feeds to the proper starting position.

• The optic system which is built into the knife cartridge tracks a position on the material.

• Once the material is indexed to the proper location, the knife assembly is triggered.

• The desiccant pouch is dispensed into bottles below which are guided by a timing screw on an adjustable speed conveyor.

An adjustable motorized equipment stand is included for easy mobility of the unit. A full Lexan enclosure separates the pouch from the outside environment.

The system, which requires 110VAC power and compressed air, includes a touch screen for easy setup and operation.

AZCO Corp. designs and manufactures modules and units used to feed, cut and place products. With a focus on the building block model concept, standard modules and units can be purchased alone or in combination to build system that meet unique needs.