Recent additions to a high-speed and highly automated glass vial filling line at Doppel Farmaceutici are helping this leading Italian contract manufacturer keep pace with marketplace demand for a popular unit-dose liquid vitamin. The primary container is an especially interesting one because it’s topped by a reservoir cap holding a powdered active ingredient. Consumers remove from the glass vial a white low-density polyethylene overcap, push a red plunger through the bottom of the reservoir cap to release the active ingredient into the liquid, shake the combined contents, remove the reservoir cap, and then drink the mixed contents.

“People really like the reservoir cap concept because they feel they are preparing the product themselves,” says Sabina Gualazzini, production manager at Doppel. “There is a perception of freshness that comes with this delivery method.”

Bormioli supplies the glass vials, the reservoir cap, and the white PP overcap.

Doppel refers to the line as Monodose 1-2. Dedicated to 7-mL vials, it’s actually a dual line whose upstream legs are similar in that both consist of the following:

• a Neri rotary air blower that blows loose any debris in the vials and vacuums it out

• a filler/plugger/overcapper; one leg of the line has a Farmomac F57, the other leg has a Marchesini (www.marchesini.com) ML 618

• a sortation/feeding device for the reservoir cap; each of these caps is filled with 150 g of powder ingredients in Doppel’s Rozzano plant some 52 miles away

• a sortation/feeding device for the overcap that goes over the reservoir cap

• a Neri pressure sensitive labeler that prints variable data on the labels

600 vials/min

These dual legs send vials into a common accumulation table at a combined rate of nearly 600 vials/min. Next in line is a Marchesini cartoner. Either of two packaging formats can be produced:

• When production calls for a retail pack holding 10 vials in a colorfully decorated folding carton, the vials are cartoned on a Marchesini BA 400 sideload cartoner. 48 of these 10-pack cartons are then case packed on a machine from PRB, and the cases are palletized on a MacDue palletizer.

• When production calls for a retail pack holding 30 vials, the Marchesini BA 400 cartoner is fed blank white cartons as opposed to printed ones. These 10-count white cartons are then diverted past the PRB case packer and sent instead to a Marchesini BA 50 sideload cartoner that encloses three white 10-count cartons in a decorated master carton. These master cartons are case packed by hand. One other piece of equipment in the line, located right after the Marchesini BA 400 cartoner, is a Model 01D3 checkweigher from Prisma Industriale.

Both the 10-count cartons and the 30-count master cartons are supplied by Galati.

The line originally operated in Doppel’s Rozzano plant. When Doppel decided to move from Piacenza, which is about 40 miles southeast of Milan, and built its glistening new facility in the nearby Italian town of Cortemaggiore, the line was moved there. Production manager Gualazzini, who joined Doppel in 1998 just four days after finishing a five-year degree program in pharmaceutical technology, followed.

“When I joined Doppel I worked more in drug design and manufacturing,” she explains. “When the company decided to build this new plant, I had a chance to remain in pharmaceutical technology or help build the new plant. I chose the new plant. It was a great opportunity to see it built from scratch, to be involved in the validation of the very first batch to come out of here.” She’s been production manager at the Cortemaggiore facility since the facility opened in 2004.

Regular upgrades

Upgrades to the Monodose 1-2 line have occurred routinely, the most recent being the addition of the Marchesini ML 618 rotary filler/plugger/overcapper. Unlike the 12-station rotary filler/plugger/overcapper on the other leg of the line, which tops out at a speed of about 250 vials/min, the Marchesini system handles 300 vials/min. It also carries liquid product to each of the 16 filling nozzles through a series of silicon tubes. These tubes are especially suitable for products having a high concentration of glucose because there is less likelihood of the product sticking to these tube surfaces than there is when product flows through valves made of ceramics or stainless steel.

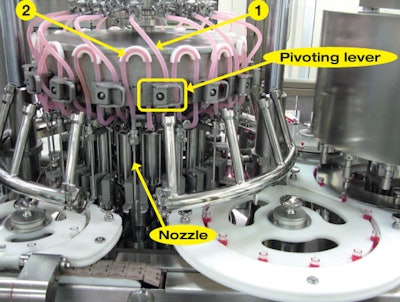

The three essential components in each of the 16 filling stations are seen best in the photo accompanying this article. (See Image 1, above). Silicon Tube 1 comes down from the main tank and passes first through a D-shaped pivoting lever before continuing underneath the filling head and connecting directly to a volumetric piston pump. Silicon Tube 2 extends upward from the piston pump and passes through the pivoting lever and then through a white C-shaped holder before extending back down and connecting to the filling nozzle. The pivoting lever pivots in such a way that when it’s pinching Silicon Tube 2, it’s opening Silicon Tube 1. While Silicon Tube 1 is open, volumetrically measured product flows from the main tank into the pump and Silicon Tube 2 is pinched closed. Then the lever pivots to close 1 and open 2, thus letting product flow from the pump into the vial and from the main tank into the pinched-off Silicon Tube 1. So with each pivot of the pivoting lever, product from Tube 2 flows into a vial and product from the main tank flows into Tube 1 so that another 7-mL dose of liquid product is ready when an empty vial enters that platform on the next revolution.

Marchesini introduced a prototype of this now-patented filling concept about 7 years ago. But commercial applications like Doppel’s have come only in the past few years. These newest versions of the technology include a no-vial/no-fill feature and improved control of the camming action on the pivoting lever so that product cutoff is improved and drips are eliminated.

“There are no stray or unintended drops falling from the nozzle,” says Gualazzini. “It’s a big improvement over older, more conventional styles of valving.”

The ML 618 at Doppel moves vials from filling to plugging to overcapping by means of starwheels. While the filling section has 16 stations, both the plugging section and the overcap application section have 12 stations.

Quality control checks on the filling/capping/overcapping stations involve Sick sensors to check fill levels in the vials, cap presence, correct positioning of cap, and height of the red part on the reservoir cap. This last measurement is crucial, says Gualazzini. “If this red piece is too high, when the white overcap is applied it could push down the red piece and cause the powder to come out and into the liquid prematurely.”

At the very head of the line is an intriguing piece of equipment from Pharma Services that feeds all of the empty glass vials that are filled on the line. An operator takes from a pallet bundles of vials that are wrapped in clear film 240 per bundle. She places the bundle on a conveyor belt that leads to the Pharma Services machine. An intermittent-motion machine, in three stations it automatically removes the plastic film and sends the vials off at a right angle to a circular accumulation table that feeds both legs of the dual filling/plugging/overcapping legs of the line. The clear film overwrap is dropped automatically into a collection bin.

Have all these upgrades and improvements gone smoothly? “Let’s just say nothing is ever easy,” says Gualazzini. “If you want to change a machine you have to produce batches and verify and seek approval from the customer. Nothing is done without approval from the customer. And if it involves primary packaging, as it did here with the Marchesini filling machine, it’s even more complicated. Cleaning, validation, and filling dosage accuracy all have to be verified.”

The bottom line is that the upgraded line runs like a clock. Other equipment upgrades are being explored now, says Gualazzini. “For a contract manufacturer like Doppel, it’s all about the customer’s needs,” she adds.