Before the Drug Supply Chain Security Act (DSCSA), European Falsified Medicines, and other global legislation, if a label convertor or a carton manufacturer could find ways to remove cost out of their packaging and pass savings along to customers, it was usually considered a major positive.

In a world where serialized content is now the norm, and where—as we learned in part 1 of Exploring the Hidden Challenges of Serialization—codes aren’t just read, but are graded, which are two very different applications.

A small change to the surface area of a plastic label could have a drastic effect on a thermal-transfer ribbon printer’s ability to adhere ribbon to the surface of a package. Changing a ribbon could be an option, but does that mean a line should be revalidated—all because of a seemingly innocuous change to a label?

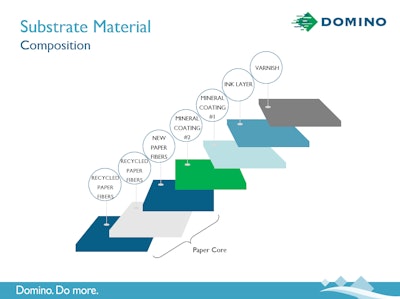

How about a carton manufacturer that attempts to do you a favor by changing the mineral layer to save costs? An incorrect mineral layer can cause a bad code, so that one-tenth of a cent savings might mean that now the laser being used can’t get the energy to absorb correctly, and now a distributor or wholesaler won’t accept your cartons. (See Substrate Materials Composition image.)

These are all changes that happen sometimes without a customer being advised, and almost always the first thing to do is blame the printer because, after all, it’s just a printer. Right?

The positive thing to take away is that as serialization becomes a larger part of the world, most label and carton manufacturers are learning that changes including the ones mentioned above—and others—can’t be done without alerting the customer anymore. Even better is that some suppliers are investing heavily into learning about material science, and imparting that knowledge on to account managers and sample lab personnel.

Printing, substrates and science

It’s important to understand how printing works, and why even small changes to substrates can have big effects on the code.

It all starts with science. Not all materials are created equally, so understanding these substrates is of the utmost importance. Domino, for example, uses equipment at its Gurnee, IL Sample Lab to analyze all incoming material to determine the contents of a set of substrates.

For laser marking it’s critical to knowing what you have in your hands and be able to identify the substrate. Using a laser to create a “wavelength match” to that substrate can mean the difference between consistent A grades and consistent C grades.

At its core, laser marking is a thermal effect. Energy is absorbed, which creates a target temperature, and ultimately creates contrast. If laser power can be provided in the proper wavelength that absorbs well, then high-grade codes are achievable. That’s not to say that high power is the key—the highest power with low or substandard absorption is still going to result in poor quality, and you’ll be using a lot of power to get that poor quality. The key is to identify the substrate, match the frequency or the wavelength, and target the correct power. (See Laser Marking-Thermal Effect image.)

The main component is still the substrate. Substrates consistent of several layers, starting with varnish, moving on to ink layers, mineral coating layers, and then fibers. Almost 80% of commonly used paperboard materials lack a key ingredient—and that ingredient isn’t in the top layer. Rather, it’s in the second mineral layer. The thickness and composition of that second mineral layer is what makes a laser mark good or bad. It’s what can cause full ablation, or issues with code modulation. It can mean the difference between a happy distributor, or an F for fixed pattern damage.

A key part of understanding material science is to use a comprehensive test document on all common carton boards available on the market.

Inks also aren’t exempt from substrate questions. Different high-density polyethylene (HDPE) bottles, or flamed vs unflamed HDPE, can cause disasters for helper codes, which is a unique code that gets married to a serialized code to help round bottles pass through a production line. (See Coding with Ink image.)

A carton or label without a good mineral layer for ink absorption can result in bleeding codes and lower grades, a lack of bonding time or worse—problems with light fastness, which is when colors change, fade, or lighten over time. Certain substrates are better for avoiding this degredation. When using ink, the stability of a code can’t just be considered immediately after printing; it should be evaluated for the full life of the product. That means testing the ink to see how it degrades over time.

Every one of these is an example of how a slight change, or an unfriendly substrate, can lead to the false assumption that a piece of equipment is the culprit for bad codes. Often, that isn’t the case. You need to evaluate your substrates—test them, ask your vendors if they’ve changed, and when needed, send some to the Domino Sample Lab for evaluation.

Editor’s note: Paul Hammond is the Pharmaceutical Sector Development Manager Pharmaceutical for Domino. More information is available by e-mail at [email protected], or by phone at 800-444-4512.