Printing and reading codes

1. Move 2D barcodes away from other barcodes on the label. Multiple barcodes, such as a UPC/EAN and a DataMatrix, on a label should be separated so that scanning is more efficient and accurate. This is especially important for hand scanning—in some situations operators had to cover a traditional linear barcode with their finger so that it would not be read.

2. Use a fixed barcode scanner on the conveyor that can read across the conveyor.

3. Watch for vibration. It can affect both printing and scanning.

4. Make sure label roll changes on label printers don’t cause serial numbers to get out of sync. In one pilot, when the printer ran out of labels, the system buffered the current label and paused to wait for labels to be reloaded. However, upon reload, the system printed the label again, causing all aggregations to be off by one. Make sure your QA process is modified to check not only whether the label printed properly, but also whether it was the correct number in the serial sequence.

5. Manual scanning slows down the process. Picking up each bottle, scanning the barcode, and putting the bottle in the case takes more time and precision than just packing the bottles in the case and taping it up.

6. Test printing on multiple carton substrates. During typical production runs, you may use multiple lots of cartons from different suppliers, each of which might have subtle but meaningful variations in printing due to substrates from different batches or board suppliers. Ensure that all conceivable variations are tested.

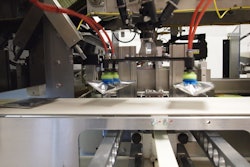

7. Use rails and clear covers to control access to serialized items on the packaging line. This helps to control sampling and product movement.

8. Employ barcode grading to detect the degradation of symbols that can result in unreadable barcodes in the supply chain when traditional hand scanners are used. Unreadable codes may result in returned goods and product shortages.

9. Control pallet aggregation to avoid cases being moved between pallets before they are wrapped.

Equipment and workflow

1. Conveyor solutions need stress testing. Ensure that the interface between the serialization application and conveyor PLC is robust.

2. Physical keyboards are easier to use than virtual ones. On-screen keyboards are difficult to use and slow down the process.

3. Adding serialized barcodes on cases in addition to normal barcodes may cause confusion. Workers may not know which barcode to scan; additional training and clear instructions will be necessary.

4. Disaggregating units from a case (or cases from a pallet) before aggregating to a shipment is inefficient. Manual rework and aggregation is extremely labor-intensive and error-prone. A process is needed that supports scanning once to perform both functions.

Software

1. Create an easy software update process. As you receive software updates from vendors, ensure the vendor is providing clear release notes for what is being updated. Work with the vendor to ensure the process to apply the upgrade is very easy and that the upgrade can be quickly validated.

2. Data volumes can clog your pipes. Some companies have found that, depending on the speed of the packaging line, the processing speeds of legacy controllers, hardware, and infrastructure on the line cannot keep up with the input/output rates associated with transmitting serialized data.

3. Beware of embedded operating systems in the packaging control system that are difficult to upgrade. As more and more serialization control systems are networked to receive batch information, an outdated embedded OS can create an issue with your network governance policies and make it difficult to use malware and antivirus software.

Liked this article? Download the entire playbook here.