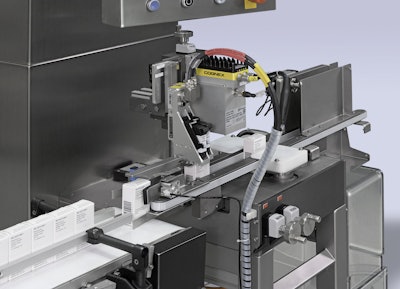

Bosch Packaging Technology has expanded its portfolio for the serialization of pharmaceutical packaging. The CPS (Carton Printing System) forms the basis of all serialization solutions from Bosch. Depending on customer requirements, the system prints 1D or 2D Data Matrix codes on up to 400 folding cartons/min. Thanks to an upgrade of the camera system, both codes can now be checked on different carton qualities even more reliably. If the contrast and readability of the Data Matrix codes do not conform to the required level of quality, the products are automatically sorted out. The machine is easy to operate from the front so that mechanical components are easily and quickly accessible in case of format changes. An optimized threading of the labeling tape reduces downtime of the CPS 1900 to a minimum.

The CPS systems can be connected to both machine software and company IT in a multi-level process, ensuring that serial numbers are attributed reliably. Depending on country and guideline, the numbers are either allocated centrally or generated by the company. Contract manufacturers in turn receive the numbers from their clients.

The Bosch machines can also be flexibly combined with systems from other IT providers. The IT concept has further advantages for production companies: Production parameters and data of all packaging lines are clearly visible at all times.

Thanks to its modular design, the CPS system can be extended by further modules. For example, a weighing module inspects the weight of each folding carton individually. Existing machines can also be equipped with a tamper-evident module. The labeler applies additional safety seals across the side flap of the folding carton, offering optimum protection against manipulation. Sensor systems carry out safe and reproducible checks of seal presence and correct application. The machine and all applications, such as the camera, are operated via a single HMI.