This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

TurboFil Packaging Machines LLC, an equipment specialist dedicated solely to the design and development of liquid filling and assembly machines, has enhanced its recently introduced TipFil™ Syringe Filling & Assembly Machine, which automates the company’s popular TipFil™ syringe filling process. Equipped with an updated platform to achieve throughput speeds up to 80 syringes per minute, the next-level machine was supplied to a customer filling pest control product in 30ml syringes.

TurboFil’s TipFil™ Syringe Filling & Assembly Machine automates all processes—from syringe loading, filling and capping through inspection, labeling and printing. The servo-driven intermittent motion machine incorporates a racetrack indexing system for rapid, reliable throughput; for multi-product manufacturers, the system also can feature interchangeable pucks to accommodate syringes with fill volumes from 1-60mls. The system can handle a wide range of product viscosities.

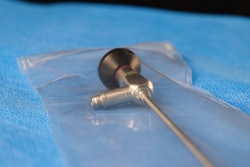

For the enhanced version, loading is performed via elevator hopper to a vibratory bowl, which transfers four syringes at a time to a tracked placement mechanism. Next, pistons are placed into all four syringes simultaneously, and advanced to the bottom of each. Dosing is performed through-the-tip via ceramic pump, with a no container/no fill sensor preventing product wastage. Metering occurs via plunger positioning sensors, with a plunger pullback mechanism reducing drips and assuring exacting fill levels.

From there, caps are placed and torqued automatically on the tips of each syringe. Once any rejects for missing components or fill volume are automatically removed from the production line, filled syringes proceed to the integrated labeler. The labeling function is facilitated by a roller conveyor that transports the syringes to the labeling head. A printer adds lot number and expiration date along with any additional necessary markings.

Ergonomically designed for efficient operation, TurboFil’s TipFil™ Syringe Filling & Assembly Machine features a 10” touchscreen HMI, Allen Bradley PLC, and three password levels for access protection. Ethernet capabilities allow for remote diagnostics, while easily identifiable buttons for emergency stop, reset, and circuit breaker-enabled on/off provide expedient line stoppage and intervention. A number of optional features are available to customize the machine to the needs of various applications.