At this year's ACHEMA event June11-15 June in Frankfurt, Multivac will present integrated offerings for packing medical and pharmaceutical products. The focus will be on the automatic infeed and packing of sensitive products, as well as packaging small batches, and for labeling and identifying products.

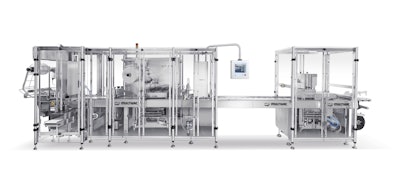

A thermoforming packaging machine (shown here) in GMP design with a single-side chain guide for packing syringes will be equipped with an automatic syringe infeed, which ensures that up to 300 pre-filled glass or plastic syringes/min can be transported and monitored with great process reliability.

The special infeed system ensures that the sensitive products are gently separated and orientated before being loaded into the pack cavities. The system's flexibility enables different types of products and pack sizes to be handled reliably. Fast and reproducible conversion of the thermoforming packaging machine is achieved through special die changing systems and the use of a complete cutting tool, which can be changed easily and quickly.

The chain guide on the thermoforming packaging machine ensures that there is simple line clearance. The monitored web advance contributes to a low level of start-up loss after batch changes. The function for running the machine empty is also designed to be simple. This means that this concept is well-suited to small product series and frequent batch changes. At the trade fair a special design with a single-side chain guide will be shown, which enables rigid film in various web widths to be used very flexibly.

Multivac will also show the semi-automatic T 260, which is specially designed for packing sensitive products in small batches. The compact model is mobile and can be used for running a wide spectrum of trays.The T 260 offers companies packing small- to medium-sized batches with a high degree of process reliability, reproducibility and flexibility. The sealing die provides controlled sealing pressure and precise temperature distribution for reproducible packaging.

The company’s C 300 TC chamber machine enables pharmaceutical products and sterile medical items to be packed securely in film pouches. Produces either vacuum packs or packs with modified atmosphere and reduced residual oxygen content. A temperature-controlled and permanently heated sealing bar, which can be both validated and calibrated, ensures that this machine achieves reproducible sealing quality.

Meanwhile, the L 300 conveyor belt labeler permits packs containing pharmaceutical and medical products to be labeled reliably and efficiently. This model applies labels to the top and bottom of packs as well as over the edge of the pack for all standard labeling tasks. Its MC 08 machine control permits this model to also be used both on a packaging line and as a stand-alone operation.

The I 410 completes checks on the packs, through to presence and position inspection of the labels. It also checks print—including pattern and character recognition, character verification and inspection of legibility and codes. With its high-resolution line scanner and image processing for both top and bottom scanning, it performs inspection of pack quality and labeling.