Concerns with glass delamination are causing many pharmaceutical companies to take a closer look at their packaging containers. Many are stability testing their products with several types of vials to find the proper combination to prevent glass delamination. Some manufacturers are using surface-treated vials to improve chemical resistance, and others are investigating the performance of these vials with their products. Nonetheless, a company's Quality Control department must be able to identify glass delamination in its products. Companies may have a laboratory with the equipment and expertise to test for glass delamination, or they may send their samples out to an independent laboratory for analysis.

Glass delamination is defined as degradation of surface glass, as from a vial, that produces glass flakes. Several mechanisms have been proposed to explain how glass delamination can occur in vials. Two common mechanisms may be (1) during manufacture when the vials are fused at the neck or base, or (2) chemical reaction with the vial contents. An indicator of adverse reactions is observed frequently at the fill line, so if a vial is stored inverted the delamination may be seen near the base of the vial instead of near the neck when stored upright.

Quite often glass delamination flakes are invisible to the naked eye. Several methods are used by McCrone's laboratory to detect glass delamination. Many times a company will send in a sample not realizing there is glass delamination. Companies that do suspect glass delamination are requested to send in their vials filled, so a determination can be made to examine if the fill line is a factor.

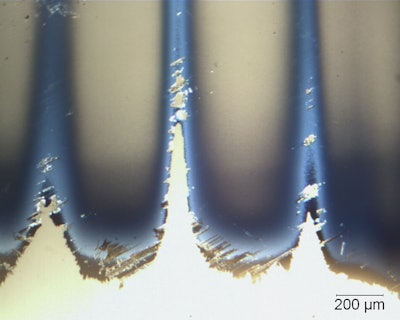

McCrone first uses a stereomicroscope equipped with several types of illumination to examine the vials. If a filled vial is received, fiber-optic oblique lighting is used to light the vial against a black background. This lighting helps to see what is referred to as a "twinkling" effect, which could be an indication of glass delamination flakes. Next, the vial's contents are emptied onto a polycarbonate filter, preferably in clean room conditions to avoid any extraneous particles. The lighting used to examine the polycarbonate filter is coaxial illumination, which causes the interference colors of the flakes to reflect back, revealing their thicknesses. Coaxial illumination is also used to examine the vial's interior, where it can reveal the location on the vial that produced the glass delamination flakes (see photo).

To identify the filtered particulate, flakes from the polycarbonate filter can be prepared for further analyses. Flakes are removed with a fine tungsten needle and placed on substrates for analysis by infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and energy dispersive X-ray spectrometry (EDS). These methods can identify the particulate as glass flakes, and provide clues to how they formed.

A further confirmatory analysis, X-ray photoelectron spectroscopy (XPS), can help determine the chemical nature of glass delamination. This analysis is performed on the interior surface of the glass vials after cutting or breaking them. XPS analysis will reveal chemical changes on the glass that are associated with degradation and glass delamination, and can confirm that the vial is the source of the flakes.

Not all Quality Control departments have all of these analytical techniques available, but most can acquire the equipment and training to perform basic examination of glass vials for glass delamination. The most useful and economical piece of equipment is a stereomicroscope equipped with oblique and coaxial lighting. This system would allow examination of filled vials to detect the "twinkling" effect associated with glass delamination, and would allow the vial interiors to be examined for glass delamination effects before and after manufacturing and product storage.

--Article supplied by Kristie J. Diebold, cleanroom manager and senior research microscopist at McCrone Associates, the analytical division of the McCrone Group. Diebold also assists in teaching an Infrared Microscopy course at Hooke College of Applied Sciences that briefly touches on glass delamination. HCAS also offers a Pharmaceutical and Sample prep class that explores glass delamination.

Glass delamination is defined as degradation of surface glass, as from a vial, that produces glass flakes. Several mechanisms have been proposed to explain how glass delamination can occur in vials. Two common mechanisms may be (1) during manufacture when the vials are fused at the neck or base, or (2) chemical reaction with the vial contents. An indicator of adverse reactions is observed frequently at the fill line, so if a vial is stored inverted the delamination may be seen near the base of the vial instead of near the neck when stored upright.

Quite often glass delamination flakes are invisible to the naked eye. Several methods are used by McCrone's laboratory to detect glass delamination. Many times a company will send in a sample not realizing there is glass delamination. Companies that do suspect glass delamination are requested to send in their vials filled, so a determination can be made to examine if the fill line is a factor.

McCrone first uses a stereomicroscope equipped with several types of illumination to examine the vials. If a filled vial is received, fiber-optic oblique lighting is used to light the vial against a black background. This lighting helps to see what is referred to as a "twinkling" effect, which could be an indication of glass delamination flakes. Next, the vial's contents are emptied onto a polycarbonate filter, preferably in clean room conditions to avoid any extraneous particles. The lighting used to examine the polycarbonate filter is coaxial illumination, which causes the interference colors of the flakes to reflect back, revealing their thicknesses. Coaxial illumination is also used to examine the vial's interior, where it can reveal the location on the vial that produced the glass delamination flakes (see photo).

To identify the filtered particulate, flakes from the polycarbonate filter can be prepared for further analyses. Flakes are removed with a fine tungsten needle and placed on substrates for analysis by infrared spectroscopy (FTIR), scanning electron microscopy (SEM), and energy dispersive X-ray spectrometry (EDS). These methods can identify the particulate as glass flakes, and provide clues to how they formed.

A further confirmatory analysis, X-ray photoelectron spectroscopy (XPS), can help determine the chemical nature of glass delamination. This analysis is performed on the interior surface of the glass vials after cutting or breaking them. XPS analysis will reveal chemical changes on the glass that are associated with degradation and glass delamination, and can confirm that the vial is the source of the flakes.

Not all Quality Control departments have all of these analytical techniques available, but most can acquire the equipment and training to perform basic examination of glass vials for glass delamination. The most useful and economical piece of equipment is a stereomicroscope equipped with oblique and coaxial lighting. This system would allow examination of filled vials to detect the "twinkling" effect associated with glass delamination, and would allow the vial interiors to be examined for glass delamination effects before and after manufacturing and product storage.

--Article supplied by Kristie J. Diebold, cleanroom manager and senior research microscopist at McCrone Associates, the analytical division of the McCrone Group. Diebold also assists in teaching an Infrared Microscopy course at Hooke College of Applied Sciences that briefly touches on glass delamination. HCAS also offers a Pharmaceutical and Sample prep class that explores glass delamination.