United Automation–an engineering and manufacturing firm specializing in the design and fabrication of custom automation equipment, and partner to Epson–has created automated labeling applicators integrating Epson’s ColorWorks C7500 on-demand color label printer and the Epson 6-Axis VT, C-Series and SCARA robot solutions. United Automation engineered the ColorWorks labeling and verification machine based on feedback from retail pharmaceutical customers that require an upgrade from black-only labels to color labels–which is becoming more important for retail pharmacies–to incorporate warnings, logos, and branding on prescription bottles. This should improve and enhance readability, comprehension of information, and safety for pharmaceutical packaging.

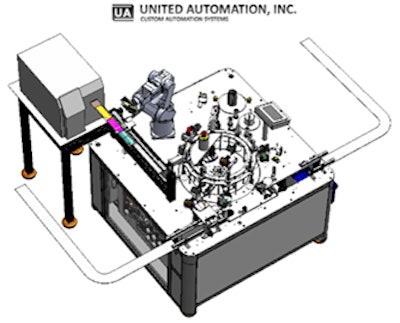

The labeling and verification machine, which incorporates the ColorWorks C7500 and an Epson 6-Axis robot, features loading, labeling, peel labeling, inspection, verification, and unloading functionalities. The labeling and verification machine for prescription bottles is designed to print and apply up to 600 unique color labels per hour with label placement precision.

The company says the ColorWorks labeling and verification machine can help simplify and streamline the process of printing and applying color labels, while first-in, first-out, in addition to inspection and verification technologies, help ensure the correct bottle receives the correct label. Also, with United Automation technology, the machine can print and apply wrap-around as well as folded labels to prescription bottles varying in height and diameter. The inclusion of the ColorWorks C7500 should provide the flexibility businesses need to help reduce waste and decrease costs associated with ordering and maintaining an inventory of pre-printed labels.

Once the bottle is detected in the machine, its barcode and label data are verified before moving along to the label station where it is greeted by its corresponding printed and folded label. After the bottle’s manufacturer and patient barcodes are verified, the bottle is moved to the peel label station where its peel label is applied and its barcode and label data are verified once again. If need be, the bottle can be rejected to the reject bin before exiting the machine.

Additional ColorWorks labeling and verification machine features include:

- Label placed over pre-existing label without covering original barcode and expiration data

- Text auto-aligned on label based on pre-determined reference point

- Label position verified at two points in cycle

- Label height adjusted dynamically based on per-bottle specifications

- Applicator reads both "picket-fence" and "ladder" type barcodes

- Folds label and applies removable adhesive tab to maximize print area