Sepha, a leak test systems provider for the pharmaceutical packaging industry, will be introducing its newly patented 3D Leak Detection technology for pharmaceutical blister packs via two live online webinars on the 2nd and 3rd December 2020. Aimed at pharmaceutical manufacturers, the new technology is designed to incorporate a 3D sensor to provide volumetric measurement to assess the integrity of a range of pharmaceutical solid dose and flexible barrier packaging.

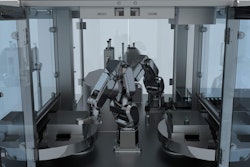

The first application of the 3D Leak Detection technology will be released with Sepha’s latest model of non-destructive blister leak testers, the VisionScan 3D. This next generation machine will use the 3D technology in combination with differential pressure and vacuum to detect leaks in individual blister pockets as low as 5µm (pack and material dependent). This technology is meant to be applied to all foil types, matt or gloss, and for different text patterns to be tested with one setting–intended for production lines with multiple language variations.

The VisionScan 3D and 3D technology have been developed for use within pharmaceutical packaging operations and in R&D environments.

The VisionScan 3D is a non-destructive, deterministic leak detection device designed to utilize the principle of vacuum deflection according to ASTM standard F3169-16. Compared with previous models (including the Blister Scan and VisionScan) this test principle has not changed. It is the new measurement technique, the 3D sensor that now creates the profile. The test area of the VisionScan 3D (297x210mm) is supposed to be large enough to cover and simultaneously test all blisters produced in one index of a typical blister line platen plate. Once the blister packs are placed inside the test area, the pack locations are automatically identified, and the test can begin.

1. Gross hole detection

The system first captures a reference quantitative topographic scan, applies a vacuum and captures a second quantitative topographic scan. At this point in the sequence, the system calculates the response of the applied vacuum in the form of volumetric change (mm3).

2. Micron hole detection

If additional sensitivity is required, the system is designed to enter the decay phase of the test. During this phase, the system adjusts and holds a vacuum for a predetermined dwell time before capturing a final topographic scan. All scans are then compared and analyzed for pocket volumetric change using product specific parameters.

3. Pass or fail screen

The results screen shows a pass or fail result for each individual pocket. If the volumetric change meets the required pass criteria, the pocket is deemed good and highlighted ‘Green’. If the pocket does not meet the pass criteria, the pocket is deemed a fail. Failed pockets are indicated ‘Red’ for gross defects and ‘Purple’ for micron defects.

Paul Smith, managing director at Sepha adds: “The VisionScan 3D offers pharmaceutical manufacturers a flexible, deterministic, and cost saving alternative to destructive blister leak test methods. In our webinars we will dive deeper into the technology, give examples of applications, and give an online demonstration of how the VisionScan 3D and its technology works. The webinar will appeal to all blister pack manufacturers that are keen to implement deterministic and non-destructive leak test solutions to improve the accuracy of their leak detection procedures and reduce cost.”

Learn more about and register for the webinar here. The webinar will also be available on demand following the live event.