COVID-19 has accelerated the digital transformation of supply chains. As full circle distribution visibility and connectivity becomes business-critical, IoT-enabled reusable packaging is playing an increasingly important role, says the article. According to a McKinsey study, the pandemic has “pushed companies over the technology tipping point,” accelerating supply chain digitization by three to four years.

Though the pandemic has caused massive supply chain disruptions and customer buying shifts that underscore the imperative nature of business agility and responsiveness, costly business disruptions from outside market forces are nothing new. In 2019 alone, according to McKinsey, 40 separate weather disasters inflicted costs of more than $1 billion per event, and that “the economic toll caused by the most extreme events has been escalating.”

Thus, product sourcing and distribution agility made possible by interconnected supply chain operations are crucial. Research from the article shows that almost two-thirds of manufacturing executives surveyed for a 2018 KPMG report said being agile is “the new currency of business; if we’re too slow, we will be bankrupt.” Connected supply chains can increase their responsiveness by utilizing digital technologies such as the Internet of Things (IoT) and artificial intelligence (AI).

IoT-enabled Reusable Packaging and the Digital Supply Chain

Reusable transport packaging (RTP) is already supporting connected supply chains. Durable enough to be equipped with technology devices, RTP are designed to work seamlessly in automated systems, provide product protection, and reduce inefficiency and waste. With the addition of IoT technology, RTP becomes the ultimate platform for load, case, and unit-level inventory visibility and data generation in the emerging supply chain, according to the Reusable Packaging Association (RPA). IoT-enabled RTP offers end-to-end, bottom-up visibility of the entire supply chain, both forward and reverse movements, when supported by business and technology models that drive data sharing. This, in turn, enhances network collaboration and breaks down limitations from silos.

Schoeller Allibert’s Smartlink Sensor, shown on the company’s JumboNest container

Schoeller Allibert’s Smartlink Sensor, shown on the company’s JumboNest container

The RPA’s 2019 white paper, A Smarter, Technology-Driven Supply Chain with Reusable Packaging Systems, describes how reusable packaging can be equipped with a variety of IoT technologies to meet the needs of business cases. It also provides information about location, condition, and other data that helps operators eliminate inefficiencies, enable effective automation, increase inventory accuracy, support predictive analytics for inventory replenishment, reduce food waste, and enhance the overall customer experience. The articke further explains that as RTP is designed to last for many use cycles, the cost of the IoT sensors can be prorated to provide an affordable cost-per-use basis.

NimbeLink’s AT6 Asset Tracker can be used on a variety of RTP

NimbeLink’s AT6 Asset Tracker can be used on a variety of RTP

The RPA white paper includes examples of IoT-enabled RTP applications:

- RFID-tagged, fast-moving consumer goods pallets can help operators improve product visibility in the supply chain and increase truck fill, thereby reducing empty miles and decreasing CO2 emissions by 62%.

- Active RFID-tagged automotive shipping racks can provide better visibility to the OEM, allowing it to reduce shipping rack inventory requirements from 5.8 days of production to 2.7 days.

- Utilizing a UHF RFID system can reduce RTP loss problems by capturing data when crates are packed, shipped, and returned. This can help companies reduce replacement expenditure on reusable crates by up to $200,000 annually.

- IoT sensor-equipped cable drums provide visibility to cable customers of drum location as well as reporting of how much cable is left on a particular drum to facilitate the return of empty drums and reordering. The system is estimated to reduce the loss or theft of drums by 90% and improve the cycle time of reusable drums by 25%.

IoT-Enabled Reusable Packaging Use Cases

The article mentions additional recent examples of how smart reusables are contributing to digital transformation:

- Postal and parcel network achieves visibility through 350,000 IoT-enabled roll containers

Beginning in June 2019, Heliot/Sigfox Germany in cooperation with Deutsche Post/DHL began installing Alps Alpine IoT sensors on roll containers for parcels. The technology has been installed on more than 350,000 containers, increasing transparency across the operator’s international European network and allowing it to improve service quality to customers. This also enabled the operator to optimize its processes while reducing the replacement of lost RTP.

Reusable roll containers equipped with tracking devices – Heliot/Sigfox Germany

Reusable roll containers equipped with tracking devices – Heliot/Sigfox Germany

- Retail floor displays provide promotional analytics to sales decision-makers

CHEP Germany recently announced the availability of IoT sensor-equipped quarter pallets that provide product manufacturers with complete supply chain visibility from plant to distribution center to the retail floor. This functionality allows decision-makers to answer questions such as when promotional displays arrive at the store and how long they remain on display. The sensor generates data based on the movement of displays and creates a full picture of the promotional campaign for manufacturers and retailers, says the article.

- RFID and NFC enabled reusable e-commerce box provides full customer delivery visibility and secure opening

Pitney Bowes forecasts that parcel volume will most likely double and reach 220-262 billion parcels by 2026, driving e-commerce companies to continually reduce costs and improve customer experience. Several reusable e-commerce packaging systems are now available. One recently introduced reusable delivery box for e-commerce features RFID and NFC technologies, along with condition sensors such as temperature and shock. The package features a rechargeable battery with a life estimated at 1,000 trips. Customers can track their packages in near real-time and tap their NFC-enabled smartphone to accept and unlock their box or reject the parcel upon receipt.

- Adaptable, IoT-ready reusable packaging that works with existing technology

ORBIS uses a 4-step approach to ensure its packaging is IoT-enabled if the customer is using IoT in their operations. 1) ORBIS collaborates with customers and vendors to identify the right IoT device options (RFID, BLE, GPS, etc.); 2) Identifies proper location and attachment on the packaging; 3) Conducts quality and validation checks and 4) Provides data to the customer’s tracking system, indicating that their IoT enabled packaging is ready to be tracked. A recent example is ORBIS’s new Odyssey Pallet which offers features to accommodate different IoT devices.

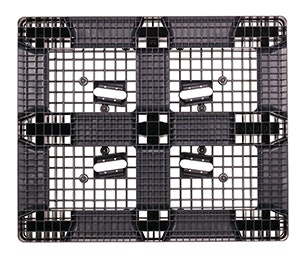

ORBIS’ Odyssey Pallet is designed to accommodate different IoT devices.

ORBIS’ Odyssey Pallet is designed to accommodate different IoT devices.