Pedigree development is viewed in the pharmaceutical industry as the approach to eliminate counterfeited products entering the authorized drug supply chain. But the big question, after all the investments and implementations in this development, is “Will the industry be able to claim that the patient will receive the authentic product when he or she buys it from authorized sources?” And, are we adopting the tools available today?

This article examines security features on packaging and whether we are encouraging the adoption of the best approach through the promotion of 2D bar codes and RFID. The article also discusses the unique identification embedded in every package based on its structure and asks if we would be better off using this ID as part of the standardized numerical identification being proposed by the FDA.

Counterfeiting becomes even more concerning today given the current economic climate, as consumers will look for less expensive drug sources, increasing the likelihood that they will end up with counterfeit products. The counterfeit product challenge is in part driven by the complexity of the drug distribution process, as shown in the accompanying “Drug distribution models” chart from the FDA's Counterfeit Drug Task Force Interim Report; 2003. The distribution process opens several holes for counterfeit drugs to enter the market.

Anti-counterfeiting measures

To this point, the counterfeiting solutions facing the industry have been to tighten up their supply chain with beginning-to-end visibility, and to adopt anti-counterfeit/anti-diversion measures. We will focus here on the anti-counterfeiting measures.

Although the industry has tried several covert and overt features to deal with counterfeiting issues, it has not been able to track back the drug product easily to the manufacturing source without a serialized 2D bar code or RFID tag. Yet the heavy emphasis on these technologies possesses flaws in providing authentication verification, as legitimate drug products are reported stolen, with the drug packaging and contents are being replaced with counterfeit product in the supply chain.

Alternative means of introducing counterfeit products with the same unique ID are possible in the current convoluted drug supply chain. When this happens, the business process system will read data from the counterfeit sources and accept the product as authentic, thereby allowing counterfeit products to enter the market. The counterfeit products need only to duplicate the unique IDs on the 2D bar code or on the RFID tag to accomplish this. This is easier than copying some of the covert and overt features currently used to combat counterfeiting. Can we settle for false positives entering the system easily after millions of dollars are invested? Are we using the best available options? This is where a technology used on packaging that captures the packaging material's unique ID adds value, similar to human fingerprinting or dental records in terms of identification and authentication.

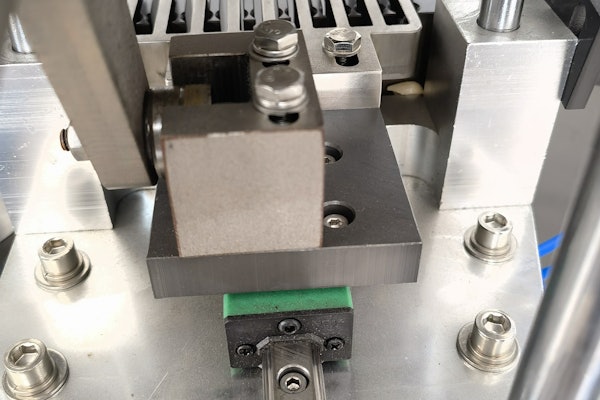

The authentication options have come a long way with the introduction of biometric technology, which can identify the packaging at item level, based on the differences inherent in the structure of the package, regardless if it's foil, solid bleached sulfate, a polystyrene-based label, or other material. Biometrics refers to methods for uniquely recognizing packaging based upon one or more intrinsic physical structures. This technology provides authentication, with track-and-trace features compatible with 2D bar codes and RFID.

All packaging materials have significant levels of nonuniformity, which can exist even in the same package, less than an inch apart. The biometric technology can take these differences and create a unique ID to develop a “package fingerprint” that can then be used either by itself, or incorporated into a serialized 2D bar code or RFID tag, truly authenticating the package.

With a claimed investment of $500,000 per line for package identification and authentication, a well thought-out e-Pedigree business process with the right authentication technologies can provide a significant return on investment.

By Narendra Srivasta, Business Development, Cortegra

Narendra Srivatsa, Ph.D., is the business development manager for Cortegra, responsible for the company's healthcare industry-related packaging products and services, including biometric authentication technology. Dr. Srivatsa has been awarded numerous process and product patents, many of which have been commercialized or licensed. A member of the ISPE, American Chemical Society, NJPHAST, ChemPharma, and other professional organizations, he has made presentations on RFID, anti-counterfeiting, brand protection, and other topics at events including FDA workshops, Interphex, and the ISPE's national conference.

This article examines security features on packaging and whether we are encouraging the adoption of the best approach through the promotion of 2D bar codes and RFID. The article also discusses the unique identification embedded in every package based on its structure and asks if we would be better off using this ID as part of the standardized numerical identification being proposed by the FDA.

Counterfeiting becomes even more concerning today given the current economic climate, as consumers will look for less expensive drug sources, increasing the likelihood that they will end up with counterfeit products. The counterfeit product challenge is in part driven by the complexity of the drug distribution process, as shown in the accompanying “Drug distribution models” chart from the FDA's Counterfeit Drug Task Force Interim Report; 2003. The distribution process opens several holes for counterfeit drugs to enter the market.

Anti-counterfeiting measures

To this point, the counterfeiting solutions facing the industry have been to tighten up their supply chain with beginning-to-end visibility, and to adopt anti-counterfeit/anti-diversion measures. We will focus here on the anti-counterfeiting measures.

Although the industry has tried several covert and overt features to deal with counterfeiting issues, it has not been able to track back the drug product easily to the manufacturing source without a serialized 2D bar code or RFID tag. Yet the heavy emphasis on these technologies possesses flaws in providing authentication verification, as legitimate drug products are reported stolen, with the drug packaging and contents are being replaced with counterfeit product in the supply chain.

Alternative means of introducing counterfeit products with the same unique ID are possible in the current convoluted drug supply chain. When this happens, the business process system will read data from the counterfeit sources and accept the product as authentic, thereby allowing counterfeit products to enter the market. The counterfeit products need only to duplicate the unique IDs on the 2D bar code or on the RFID tag to accomplish this. This is easier than copying some of the covert and overt features currently used to combat counterfeiting. Can we settle for false positives entering the system easily after millions of dollars are invested? Are we using the best available options? This is where a technology used on packaging that captures the packaging material's unique ID adds value, similar to human fingerprinting or dental records in terms of identification and authentication.

The authentication options have come a long way with the introduction of biometric technology, which can identify the packaging at item level, based on the differences inherent in the structure of the package, regardless if it's foil, solid bleached sulfate, a polystyrene-based label, or other material. Biometrics refers to methods for uniquely recognizing packaging based upon one or more intrinsic physical structures. This technology provides authentication, with track-and-trace features compatible with 2D bar codes and RFID.

All packaging materials have significant levels of nonuniformity, which can exist even in the same package, less than an inch apart. The biometric technology can take these differences and create a unique ID to develop a “package fingerprint” that can then be used either by itself, or incorporated into a serialized 2D bar code or RFID tag, truly authenticating the package.

With a claimed investment of $500,000 per line for package identification and authentication, a well thought-out e-Pedigree business process with the right authentication technologies can provide a significant return on investment.

By Narendra Srivasta, Business Development, Cortegra

Narendra Srivatsa, Ph.D., is the business development manager for Cortegra, responsible for the company's healthcare industry-related packaging products and services, including biometric authentication technology. Dr. Srivatsa has been awarded numerous process and product patents, many of which have been commercialized or licensed. A member of the ISPE, American Chemical Society, NJPHAST, ChemPharma, and other professional organizations, he has made presentations on RFID, anti-counterfeiting, brand protection, and other topics at events including FDA workshops, Interphex, and the ISPE's national conference.