This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Syntegon, a provider of pharmaceutical packaging solutions and process technology, highlights the Versynta microBatch solution, a groundbreaking innovation in small batch processing designed to meet the stringent requirements of the pharmaceutical industry.

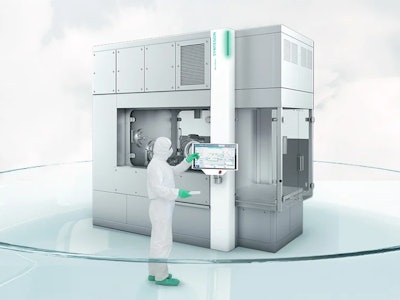

The Versynta microBatch is a highly flexible and fully automated production cell that sets new standards in the fill/finish processing of aseptic and high-potent micro batches. This gloveless isolator system is specifically engineered to address the growing demand for small batch sizes in the production of biopharmaceuticals, cell and gene therapies, and other high-value medicines.

The system features a gloveless isolator with significantly reduced bio-decontamination times, eliminating the need for glove testing and management. This design minimizes manual intervention, thereby reducing the risk of contamination. The Versynta microBatch is fully automated, ensuring precise and consistent processing. Automated setup for the filling path, format parts, and monitoring further enhances efficiency and reliability.

Integrated air management is another key aspect that simplifies room integration and reduces the need for interfaces with the building or technical ceiling installations. The Versynta microBatch is designed to handle a wide range of Ready-To-Use (RTU) containers, including syringes, vials, and cartridges, along with various closure systems such as classical stoppers, crimp caps, and press-on caps.

The system ensures maximum security with 100% in-process control during the filling process, minimizing product loss and ensuring that high-quality product is filled accurately. Fast batch-to-batch changeovers are also a significant advantage, with the ability to change batches in as little as two hours, optimizing production efficiency and reducing downtime.

Advanced monitoring concepts are integrated into the system, ensuring the highest product quality and compliance with stringent regulatory standards such as Annex 1. The Versynta microBatch has a compact footprint, making it easily integrable into existing production environments.

Syntegon's Versynta microBatch has been recognized with the Parenteral Drug Association’s Innovation Award, a testament to its innovative design and industry-leading capabilities. The Versynta microBatch from Syntegon represents a significant advancement in small batch processing, offering unparalleled flexibility, automation, and quality control. This innovative solution is poised to revolutionize the production of high-value medicines, ensuring product is handled with the utmost care and precision.