Key takeaways:

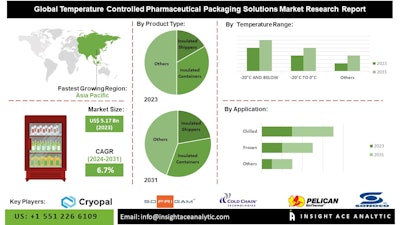

· The market is estimated to reach over $8.64 billion by 2031, exhibiting a CAGR of 6.7% during the forecast period.

· The growing use of highly temperature-sensitive biologics and customized medications is one of the main factors propelling this market.

· Advancements in biodegradable materials and smart packaging technologies, is also driving growth.

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the “Temperature Controlled Pharmaceutical Packaging Solutions Market”- , which is estimated to reach over USD 8.64 billion by 2031, exhibiting a CAGR of 6.7% during the forecast period.

Temperature-controlled pharmaceutical packaging solutions refer to specialized packaging systems designed to maintain the required temperature range for pharmaceutical products during storage and transportation. These solutions are critical for preserving the integrity, efficacy, and safety of temperature-sensitive medications, such as vaccines, biologics, and other pharmaceutical products. They use materials with high thermal resistance to protect products from temperature fluctuations and active temperature control systems like refrigerated containers or coolers to provide a constant temperature. Electronic systems provide precise temperature control through refrigeration or heating mechanisms. These packaging solutions are essential for ensuring that pharmaceuticals remain effective from the point of manufacture to the end user, particularly in global distribution where products may encounter varying climatic conditions.

The market for temperature-controlled packaging solutions is expanding significantly due to increased demand from the food, pharmaceutical, and healthcare industries. The integrity and security of temperature-sensitive goods during storage and transportation are dependent on these businesses' use of efficient packaging solutions. Strict legal requirements for product safety and quality, new developments in insulating materials, and the growing demand for cold chain logistics are some of the main motivators. The market is expanding as a result of advancements in biodegradable materials and smart packaging technologies, which provide long-term answers to environmental issues on a worldwide scale.

Market Segmentation

The is segmented based on product type, temperature range and application, and by region. By product type, the market is segmented into insulated shippers, insulated protective shippers, and insulated containers. Insulated shippers segmented into panels & envelopes, EPS foam containers, fibreboard, and PUR containers. Insulated containers are segmented into chest style, upright style, and others. Temperature Range segment includes -20°C and Below, -20°C to 0°C, 2°C to 8°C, 8°C to 25°C, and Above 25°C. By application, the market is segmented into frozen, chilled, and ambient.

The insulated containers segment is expected to have the highest growth rate during the forecast period. They offer significant capacity for storing and transporting pharmaceuticals, vaccines, and biologics in bulk. Used extensively in cold chain logistics for pharmaceutical distribution, especially for long-distance transport where maintaining temperature integrity is critical. The demand for insulated containers is driven by the expansion of biopharmaceuticals, vaccines, and specialty drugs that require stringent temperature control.

Based on the application, the chilled segment dominates the market. This segment caters to pharmaceutical products that require storage and transportation at temperatures typically ranging from 2°C to 8°C. Many biologics, vaccines, and specialty drugs fall into this category. The growth in biopharmaceuticals and vaccines, which often require chilled storage to maintain efficacy and safety, drives demand for sophisticated temperature-controlled packaging solutions.

The Asia Pacific region is experiencing rapid economic growth, leading to increased healthcare spending and infrastructure development. This growth supports the demand for pharmaceutical products, including biologics, vaccines, and specialty drugs that require stringent temperature control. With a growing population and rising healthcare awareness, there is a heightened demand for vaccines and biologics across Asia Pacific. These products are highly sensitive to temperature variations and require reliable temperature-controlled packaging solutions.