Terminal sterilization protects filled pharmaceuticals from microbes and ensures they are safe to use. However, the sterilization process is subject to differing requirements depending on both medication and primary packaging, posing various challenges to pharmaceutical manufacturers.

How high can a sterilizer’s temperatures be without damaging the efficacy of temperature-sensitive drugs? What pressure conditions are needed to maintain container stability? Sterilization tests help to determine each product’s processing parameters, from supporting pressure to loading procedures, thereby ensuring pharmaceutical product safety.

At first glance, a syringe reveals little about how complicated its production is, from developing the solution, choosing and filling the packaging to designing the container. Even after filling, the process is not yet completed. For instance, depending on the active ingredients, many countries require terminal sterilization of prefilled syringes to ensure the safety of both product and patient.

Parenterally administered pharmaceuticals, such as heparin preparations in syringes and infusion solutions in bags or bottles, generally place high demands on the sterility of the packaging. All these products need to remain free of microbes to prevent infections after administration. Terminal sterilization of the packaged drugs eliminates microorganisms to the maximum extent in accordance with official regulations.

The challenge of plastics

Especially for new products, pharmaceutical manufacturers increasingly rely on customized packaging made of plastic. These are often developed in close cooperation with primary packaging manufacturers to fulfill very specific design and marketing requirements.

During terminal sterilization, however, plastic containers may burst, warp or lose strength, making them unusable. Potential negative impacts on the product’s final validation entail long delays and additional costs for the manufacturer. As a result, pharmaceutical and packaging producers must create the ideal sterilization conditions for different types of medication and containers. Here, invaluable support is provided by suppliers of sterilization equipment with a range of product-specific processes and comprehensive sterilization tests.

Terminal sterilization is precisely tailored to pharmaceutical requirements. Depending on the medication and the approved procedure, different cycle times, temperatures and sterilization media are needed to ensure the containers remain sterile and intact, and the filled ingredients maintain their integrity. This can be accomplished by various different sterilization methods.

Among the industry’s most common and preferred methods are the vacuum-steam process, the steam/air mixture process, and the hot water shower. Modern combined systems incorporate multiple processes within a single sterilizer, offering greater flexibility in terminal sterilization.

The appropriate process for each product

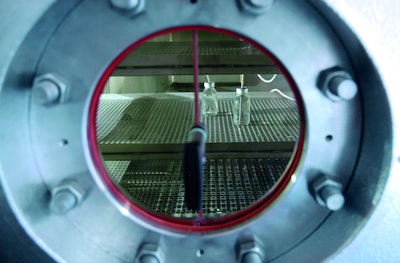

Solid and porous equipment, prefilled ampules and blister-packed products are sterilized using the vacuum-steam process. The air is completely evacuated from the pressure chamber and containers, ensuring saturated steam to penetrate even into the tiny cavities of porous items like plastic stoppers. The latter are subsequently heated and sterilized by inflowing pure steam. Depending on the type of load, the process finishes either with vacuum drying or jacket cooling.

Open, semi-sealed and completely closed containers such as vials and prefilled syringes, as well as mono- and multi-chamber bags are sterilized by the steam/air mixture process. It allows products to be removed in a dry condition at the end of the cycle. The direct inflow of steam, which is circulated by fans inside the chamber, provides for heating and sterilization, while cooling is accomplished by internal heat exchangers. Supporting pressure can be adjusted as desired, thus preventing deformation, excessive stopper movement and container breakage throughout the entire cycle.

The hot water shower is particularly suitable for liquids in closed containers, such as blow/fill/seal products and closed IV bags. Fast heating and cooling cycles reduce thermal stress on temperature-sensitive products to a minimum.

Considering all process parameters

Liquids and packaging are subject to variable thermal and mechanical stress. In case of too high pressure within the containers, walls may soften or bag seams burst. To prevent syringe and vial stoppers from shifting within the containers, a so-called supporting pressure is generated in the sterilizer. Thermally instable pharmaceuticals risk to spoil when exposed to high pressures and temperatures, losing their effectiveness. Precisely tailored sterilization parameters for liquids and containers are crucial. But how can the necessary formulations be determined?

Pretests including essential process parameters such as loading, temperature, pressure, heating and cooling speeds, as well as product storage are key. Depending on container quantity and complexity, test runs can take from a few hours to several days. They precisely map the sterilization processes required by different products—and in case of doubt, they identify whether a new product or primary packaging material can be sterilized at all.

Pharmaceutical and packaging manufacturers not only receive extensive documentation and practical guidance. The tests also provide them with important indications to further optimize their products and sterilization processes.

Negative results just as useful

The required sterilization procedure for approved drugs has normally already been defined. In this case, test results can deliver valuable insights regarding which variables have to be adjusted in order to achieve even more efficient process and cycle times. The same applies to containers.

Packaging manufacturers receive a detailed analysis of a container’s characteristics and potential weaknesses, resulting in important clues on how the packaging might be optimized. In case of a projected production line expansion, an evaluation of the loads capacities ascertained by comprehensive testing helps to determine the suitable size of the installation. Pharmaceutical manufacturers can thus invest in expansion projects according to their exact requirements, while saving time and avoiding unnecessary costs.

If correct procedure and parameters are still to be determined, test runs can be conducted as a kind of “stress test” to answer questions regarding “sterilizability” and packaging quality, as well as the most suitable procedure. Manufacturers save a great deal of time and effort during qualification and validation, and can accelerate the product’s market launch. Even if the test results are negative, they will certainly not lead to the cancellation of production.

Instead, packaging and pharmaceutical manufacturers can target their efforts more accurately and accelerate the further development of their respective products. Moreover, specialized testing centers are also available to manufacturers who either do not own the right equipment or whose machines are already working at maximum capacity. Outsourcing sterilization tests to experienced equipment manufacturers is an alternative that saves both time and money—while manufacturers and patients are always on the safe side.

—Author Isa Alkan is Sales Director, SBM Schoeller-Bleckmann Medizintechnik Ges.m.b.H., Bosch Packaging Technology Company. Bosch Packaging Technology – product division Pharma is a provider of process technology and packaging solutions for the pharmaceutical industry.