This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

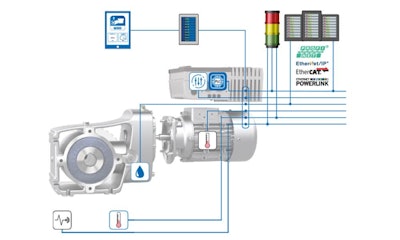

The Nord condition monitoring solution utilizes the internal programmable logic controller (PLC) within the variable frequency drive to integrate drive-related actuators and sensors into a system that detects undesired operating conditions at an early stage. Drive and status data are recorded periodically or continuously. The results are then provided via the PLC output parameters, and can be sent and saved to a local dashboard via Industrial Ethernet for visualization. An interface for digital and analog sensors, including virtual sensors, enables the PLC to calculate information, such as the optimal oil change time.