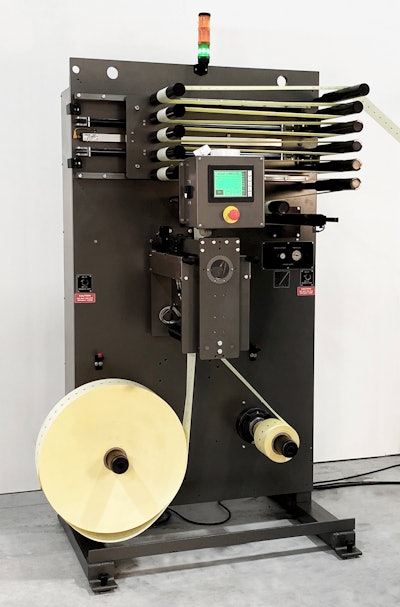

Quantum Design, a Control Systems Integrator and owner of several equipment product lines serving the packaging industry, today showed its Clamshell Splicer on its CTC converting equipment product line.

The Clamshell Splicer is designed to offer flexibility and reliability, in order to save money, time, and raw materials. It’s horizontal prep. low roll loading height, pneumatic brake system, and adjustable tension control system with horizontal web festoon are intended to make this lap splicer user-friendly and efficient. These features allow the operator to prep the next roll while the current roll is running.

The Clamshell splicer works with a wide variety of materials and operates at speeds up to 600FPM. Unveiled at PACK EXPO Connects were the splicer’s newly designed PLC controls with HMI touch screen and minimal power requirements for easy integration into existing packaging lines. The machine can also send a signal to the packaging machine to activate a waste chute or similar device which is timed to eject the pouch that contains the splice. Additional options include right or left configuration, up to 6 core shafts, remote diagnostics ready, 30” roll diameter sizes, and in-register splicing for pre-printed webs.

To watch the demo, click here.