This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

At the upcoming ACHEMA 2015 in Frankfurt/Main, the Romaco Group will show end-to-end solutions for granulation and coating, tableting and primary and secondary packaging. Romaco will additionally unveil a blister line with an integrated anti-counterfeiting system which enables the primary packaging to be unequivocally identified. A new aseptic microdosing machine with one hundred percent weight control and the next generation of Romaco’s Remote Assist will also be among the technological highlights.

Romaco Innojet: Granulation and coating based on air flow bed technology

With its acquisition of Innojet Herbert Hüttlin in February 2015, the Romaco Group became the first supplier in the world to manage the entire process chain for manufacturing and packing pharmaceutical solids. Romaco Innojet’s high-efficiency solutions for gentle granulation and coating processes are based on the patented air flow bed technology. Originally developed by Dr. h.c. Herbert Hüttlin, this method particularly impresses with its linear scale-up of all process parameters and allows up to 75 percent shorter processing times compared to conventional technologies. The optimised process control results from the cylindrical design featuring five patented functional components: ORBITER, VULCANO, ROTOJET, LINEAJET and SEPAJET. The Romaco Innojet exhibit will include the VARIOSCALE VS 40 system module – the world’s first coating system for totally variable batch sizes, which represents the ideal choice for solid particles such as tablets of any size and shape as well as soft or hard gelatine capsules. The VENTILUS series was explicitly created for granulating and coating fine solid particles as small as three millimetres in diameter. The product to be treated is agglomerated with a spray liquid and/or coated and dried, depending on the application. Visitors to the trade fair will also have a chance to watch a live demonstration of granulation and coating processes based on the air flow bed technology. Romaco will showcase various processes on the laboratory scale Innojet VENTILUS V 2.5. An Innojet VENTILUS V 400 processing machine for a maximum batch size of 400 litres will likewise be on display along with laboratory and pilot scale systems belonging to the Innojet AIRCOATER series.

Romaco Kilian: Cool, Fast, Clean – European market launch of the Kilian KTP 720X

Following the market launch of the Kilian KTP 420X single-sided rotary press at Interpack 2014, Romaco Kilian’s double-sided version – the Kilian KTP 720X – will make its debut this year at the European ACHEMA trade show. This high speed press, designed for manufacturing mono and bi-layer formats, compresses up to 1,020,000 tablets an hour. Both presses in the KTP X series are eminently suited for processing temperature sensitive products like Ibuprofen or Metformin. Optimal cleanability in mono mode and rapid batch changes were key design priorities. Thanks to the large HMI panel with swipe functionality, the Romaco tablet presses are moreover very simple to operate. Romaco is the first manufacturer worldwide to offer high tech tablet presses featuring the innovative, integrated CWC system, which measures the weight of the tablets continuously while they are being produced. The STYL’ONE Evolution single-stroke tablet press, on the other hand, is predestined for formulating mono-layer, multilayer or core tablets (tab in tab) in a broad array of R&D applications. The production process on any standard rotary press can be simulated precisely using the integrated ANALIS software. As a tableting robot, STYL’ONE Evolution can also be utilised in a targeted way to make manufacturing processes more efficient or troubleshoot errors. The time and expense which are normally unavoidable for development activities or to optimise products and processes are restricted to a minimum – a great advantage for users.

Romaco Macofar: World first for aseptic microdosing

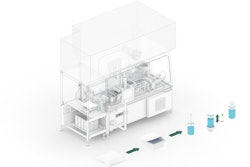

The Macofar MicroMaxX 18 microdosing machine will introduce Romaco’s brand new product family, which continues the manufacturer’s decades-long tradition of innovative solutions for aseptic microdosing. The Macofar MicroMaxX 18 provides exceptionally high flexibility. It is equally suitable for processing pharmaceutical powders and sterile liquids and meets all the requirements for downstream freeze-drying. The two dosing discs allow multiple dosing into the same vial, so that the product can be filled in two process steps. Thanks to a new, innovative weight control system, all vials can be weighed individually in-line, so that one hundred percent accurate weight control is now possible for the first time. The Macofar MicroMaxX 18 is the fastest in the market today with one hundred percent dosing accuracy, with an output of 12,000 vials an hour. In the standard version with statistical weight control the system achieves up to 18,000 vials an hour. The microdosing machines can be equipped with various containment systems and sterile external access to all components is assured via glove ports. The cGMP compliant design of the Romaco Macofar MicroMaxX 18 thus satisfies even the most stringent requirements for filling sterile powders and liquids. The MicroMaxX 18 can be seen at the exhibition in line with the new Macofar MAC 4 capping machine.

Romaco Noack: Anti-counterfeit blister solution

The Romaco Group will take advantage of ACHEMA to introduce its Noack 960 blister solution with integrated anti-counterfeiting system for pharmaceuticals. The new technology, developed in an exclusive partnership with NANO 4 U, meets all the requirements of the EU’s Falsified Medicines Directive 2011/62/EU. A unique stamped hologram, which identifies each blister unequivocally, provides proof of originality. This cGMP compliant blister system built by Romaco Noack additionally boasts short cleaning times, quick format changes and an advanced level of automation. The Noack 960 blister machine is offered with rotary or platen sealing and packs pharmaceutical solids in a variety of shapes and sizes. The interchangeable QuickFeed unit enables parallel operating steps instead of sequential. Thanks to the patented technology, product changes are completed in less than thirty minutes. When installed in an in-line configuration with the Romaco Promatic PC 4000 continuous motion cartoner, as it will be at the upcoming ACHEMA, the Noack 960 blister solution has a maximum output of 700 blisters and 420 cartons a minute.

Romaco Siebler: Integrated strip packaging solution

Format and product changes are both quick and easy with Romaco Siebler’s integrated strip packaging machine. The cut strip packs are transferred by the FlexTrans FT 1-600 transfer station to the Romaco Promatic P 91 intermittent motion cartoner. The flexible-format transfer module is controlled by three FlexPicker robots, which were developed to handle a maximum of 600 strips per minute. Thanks to its QuickSeal technology, the Romaco Siebler HM 1 heat-sealing machine is capable of delivering up to 3200 tablets a minute. Multiple heaters per sealing tool enable air, light and moisture-tight, four-sided sealed foil packs to be produced at very high speed. The specimen seals are individually adapted to ensure premium sealing quality while all process parameters are absolutely reproducible. The products are fed to the sealing station, perforated and cut to the required size in up to eight lanes. Owing to the strict balcony architecture and cGMP compliant design, the Romaco Siebler HM 1 is also very straightforward to operate.

Romaco Promatic and Pharm-Tech (Tianjin): integrated stick packaging solution

Romaco will take advantage of the trade fair to present the new XDJ50 stick packaging line, featuring an integrated Romaco Promatic P 91S cartoner, jointly with its cooperation partner Pharm-Tech Co. Ltd (Tianjin). The stick packaging machine has between two and twelve lanes which can be equipped with various feeders for filling powder, granules, tablets, capsules or liquids. Several integrated systems guarantee highly reliable processes: the sealing temperature and pressure are monitored automatically, as are the alignment and integrity of the film. The direct connection to the Romaco Promatic P 91S intermittent motion cartoner permits end-to-end packaging concepts.

Romaco Remote Assist

The next generation of remote service will be presented by Romaco under the motto “push the button”. The HMI panels of Romaco machines will be provided for this purpose with a special support button, which activates a remote online support case immediately when pushed. The master data of the machine concerned is then transmitted to Romaco automatically together with the relevant process parameters and the current error message. This saves valuable diagnostic time and the service engineer can set to work to find a solution without delay. All support requests received by Romaco directly via an HMI panel are dealt with centrally regardless of the location. The new support platform provides secure data transfer and seamless tracking, so that customer requests for assistance can now be processed much more efficiently. In future, users will also have the option of communicating directly with the Romaco service team using smart glasses. Romaco will demonstrate the new Remote Assist system at ACHEMA on the Noack 960 blister line.

On show at ACHEMA, Frankfurt/Main (Germany), from June 15 to 19, 2015 (Hall 3.0, Stand B49).

>> For more information, click here