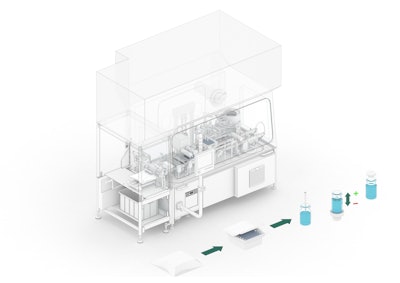

Groninger introduces FlexPro 50, an aseptic pharmaceutical line for nested containers. The system was designed to meet the demand for a flexible solution to the aseptic filling of pre-sterilized containers for small batch processing in isolators.

The newly developed and highly flexible series for aseptic processing of nested syringes, cartridges, and vials permits a host of configuration options in a modicum of space. Co-developed with isolator manufacturer Franz Ziel GmbH, this modular machine concept was developed in various stages of automation. Based on the ready-engineered philosophy, outputs of up to 5,000 containers/hr are achieved. The line consists of a semi-automatic bag opener and fully automatic units for opening tubs and filling and closing of the nested vials.

This isolator system offers safety of the filling and closing process, particularly as an aseptic production line for small batches that demand the highest standards of product safety or as a laboratory line for clinical tests. The in-process control permits 100% control of filling results, thus guaranteeing sterility at every process stage. Another line highlight is the decontamination unit for the syringe tubs. Reduction of potential contamination using plasma technology complies with cGMP requirements.