In the world of blister packaging, non-destructive testing continues to gain popularity for increasing efficiency and reducing total cost. Traditional methyleneblue dye testing destroys products and/or packaging, promoting environmental waste and causing manufacturers to flush money down the drain.

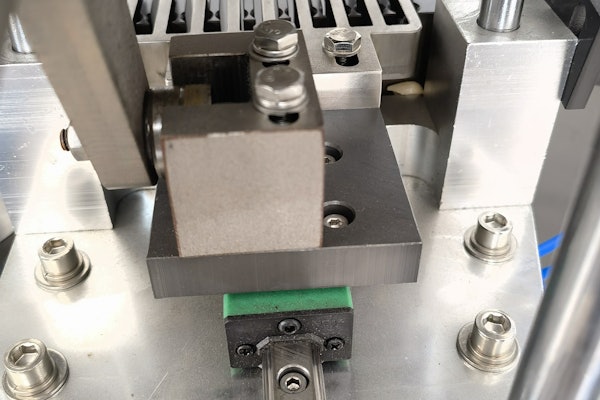

With Sepha’s next generation VisionScan System, pharmaceutical manufacturers can obtain accurate, efficient blister seal and leak detection results without destroying product or packaging. The machine uses updated high resolution imaging technology that detects defectsin individual blister pockets, channel leaks and weak seals down to 15 microns. Because the image scanning method is non-destructive (both clean and dry), tested product can be retrieved from faulty packs and repackaged, cutting down on unnecessary product waste.

In terms of compliance, the detection system is preferable to manual inspections as the testing is subjective. Earlier detection of leaks allows line operators to investigate and troubleshoot the cause of the nonconformances more quickly, limiting the production of faulty packs. As documentation is a necessary part of any quality assurance process, the system is capable of storing and exporting data for auditand quality control purposes.

VisionScan, distributed in North America by Thomas Packaging, is operated via touchscreen and requires no tooling, making it a useful tool for high-volume pharmaceutical manufacturers and packagers where high levels of quality control, cost reduction and multiple product changes are required. The original VisionScan is sized for benchtop use, while the larger VisionScan Max can test up to 600 blister packs per hour.

The operating system can store up to 30,000 product types containing capsules or tablets. Additionally, R&D departments can use the rapid testing in drug stability studies when analyzing materials for protection against moisture, air and bacteria.