The technology involves coating the DataLase material—a stable, inorganic pigment in the form of a white powder—onto packaging materials such as carton stock during converting. Or it can be used as a coating applied during the printing process. This laser-reactive surface becomes an integral part of the package and cannot be removed. The laser creates a clean, high-resolution bar code, logo, or graphic onto the surface.

One DataLase “labeling” application is now moving from the trial stage to commercialization with an undisclosed medical device company in Europe. According to Andrew Jackson, Sherwood’s applications marketing manager, the device maker uses DataLase to replace thermal-transfer print-and-apply labelers, eliminating the need for pressure-sensitive paper labels and inked ribbons, and the maintenance associated with the printer-labelers.

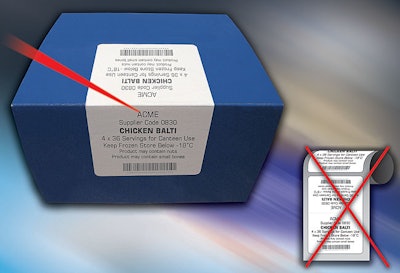

The application uses two levels of DataLase—one for the inner blister packs containing syringes or ampoules, and another on the secondary cartons containing four or five of the blister packs. Each blister measures 2” X 1”.

The blisters are flood-coat printed with the DataLase material and laser-marked with alphanumeric product name, lot number, storage instructions, and traceability information. That’s done immediately after the blisters are sealed.

Those are packed into a 9’’-square paperboard carton with product identification and bar code printed by the laser while the carton is stationary. Information that had been printed on a label is now coded directly on the carton into a white area that matches the dimensions of the previous label. —Rick Lingle

Subscribe to Packaging Insights newsletter free at www.packworld.com/newsletters