When thinking about automation projects, it seems natural for most consumer product goods (CPG) manufacturers to think first about how equipment can improve a process, increase productivity, and reduce labor costs. After all, it’s easy to visualize how a few cobots can speed up end-of-line product packing and eliminate the need for several people performing the same task. But there’s another side to the automation equation that can yield significant productivity improvements as well: digital transformation (DX). Some recent data shows just how significant these improvements can be.

In its 2022 Global Food and Beverage Industry Trends report, International Data Corp. (IDC) revealed that companies adopting digital transformation into their operations have seen a measurable increase in productivity and profits. About three-quarters of the survey respondents have seen KPI improvements across all areas of the business (production, quality, supply chain, logistics, sales, e-commerce) as a result of their digital transformation initiatives, and an additional 45 to 55% expect to see even more improvements over the next 12 months. Companies investing early in digital transformation are now reaping the benefits, IDC concludes, and those still sitting on the fence are at a potential disadvantage.

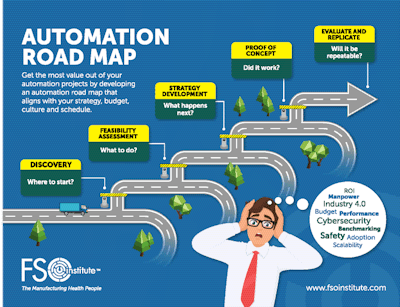

Using the FSO Institute’s Automation Roadmap (see opposite)—especially the first two stops, Discovery (Where to Start?) and Feasibility Assessment (What to Do?)—we’ve asked FSO coaches and roadmap contributors John Giles (formerly Amway) and James Couch (formerly Smithfield Foods) to weigh in on the advantages of thinking beyond equipment to digital transformation in the early stages of automation projects.

FSO Institute: John, you’ve had some significant successes with collaborative robots (cobots). Did the “equipment first” or “beyond equipment” thinking reflect your own experiences with these automation projects? How do/did you convince others to move in the direction of digital transformation and do/did you see the benefits cited by IDC?

John Giles: I think that, like many companies, our main driver for implementing cobots across our manufacturing plants was driven by the labor shortage issues that we were facing at the time. The cobots were simply brought in as one way to help resolve our labor issues, which were brought on by very low unemployment creating a tough job market, combined with a wave of retirees that was just starting to impact operations. Based on these factors, we knew we needed to get in front of the situation as much as possible, and cobots were one of the approaches to help mitigate our labor shortage issue.

One of the keys to success for our cobot deployment was the formation of a small, dedicated automation team that was composed of a mechanical engineer, a controls engineer, a maintenance technician, and a manufacturing technician. This created an initial group of experts that were able to quickly investigate potential applications and help prioritize the areas where the cobots would provide the most justification. Research and training were essential for these team members to help them be effective and highly skilled. As the team progressed and started system installations, training line operators and maintenance staff became another essential deliverable for this team.

Applying DX for us was primarily focused on full production lines with dedicated equipment, including conventional industrial robots. Many of our standalone cobot applications were not plugged into our data systems to keep things simple and promote ease of use and setup. However, some of the slower lines did use dedicated cobots, primarily for palletizing or case packing operations, and these were digitally monitored for all typical KPIs for that line. Like any of the other equipment on the line, we were able to monitor their performance and this information was used to verify that our original justifications for the cobots were valid.

To answer your question more directly, we were definitely motivated by “equipment first,” but realized that we could easily integrate the cobots into our traditional data systems in order to monitor and track their performance. For us, digital transformation was not originally a strong motivator or part of the justification used for these installations. However, once we became more familiar with their capabilities, we definitely realized the benefits of “plugging” these in and making them part of the data stream.

FSO Institute: James, you’ve been through numerous automation projects. What’s been your experience in the early stages (Discovery and Feasibility Assessment) of the FSO Automation Roadmap regarding the balance between equipment and digital transformation? Have you seen the kind of benefits cited in the IDC findings?

James Couch: I believe that most food and beverage companies struggle with implementing DX projects due to a lack of understanding about the process. As we all know too well, there are numerous buzzwords out there today that confuse the end users and thus polarize the initiative.

The key to implementing a DX process is to keep it simple. It does not have to be complicated or expensive, but it must bring value to the organization to be successful. You need a roadmap. I believe before any company takes on the initiative of DX, they should Think Big, start with the end in mind; Start Small, pick the process that will be easy to implement and supply a quick result; and Make the Process Scalable, ensure that your process is repeatable.

Basic elements of a successful DX project start with strategy and leadership. This requires communication with stakeholders and a team-structured process. The organization is about to embark on a culture change that will change its way of working. This process will change how they operate and deliver value and will challenge the status quo.

The first significant stage of a DX process is the alignment process. Senior leadership must see the value the process will bring to the organization. In this post-pandemic era, everyone wants to automate their processes. There are five basic steps to implementing a successful DX process, starting with the discovery phase. You should first understand where your organization resides relative to performance. Calculating the overall equipment effectiveness (OEE) on equipment or a production line is the best place to start. Once you have determined the best potential opportunity to implement your DX initiative, you will move to phase two, the feasibility study. This phase will show the associated cost and value the process will bring to the organization.

There are a few tools that should be considered as you begin the DX process and plan for your feasibility study. Do you have an existing manufacturing execution system (MES) that you will incorporate into this process? Do you plan to keep this data local, at the machine or line level only? How will you track and check performance to your KPIs? How will you convey and communicate real-time performance to you staff? Ultimately, what does success look like? All of this speaks to the Think Big segment. You will need a solid foundation for your program to be successful and build upon.