Considering that you’re now browsing Packaging World magazine's website, chances are good that you’re with a brand owner or CPG company in a capacity related to packaging operations. And if you tick that box, then it’s almost certain that you’re at least adjacent to projects aimed at improving your products’ overall sustainability profile. Brands have imposed upon themselves target dates to meet these commitments, usually a round number like 2025 or 2030 that some worry are impractical. But to be fair, with such lofty goals, what’s practical might be the enemy of what’s possible. Not to mention, people like nice, round numbers for target dates.

Meanwhile, upstream from you, converters and other packaging suppliers are working to develop more sustainable materials that they can sell to your operation. In the case of PCR, they’re first searching for a dependable supply. Once having secured that (which is no guarantee), they’re then asking recyclers for higher quality materials.

And downstream from you, retailers are laboring under sustainability goals of their own, perhaps making your products’ sustainability profiles a factor in how much space you’ll get on their retail shelves, if any. All these stakeholders’ distinct and disparate efforts are due to consumers who say they are actively seeking out products with more sustainable packaging.

But too often, each stakeholder, or each rung on the ladder, is operating in a silo. The links on the supply chain to the left and to the right of the CPG/brand have their own sets of KPIs to hit, and those may not always align with yours. Sometimes it seems like everyone’s taking a different path, separately hacking their way through the wilderness toward what should be a common destination. That’s why a groundbreaking partnership led by Minnesota’s MBOLD coalition, still in its infancy, is worth keeping an eye on.  Recyclable store drop-off polyethylene film used in Nature Valley granola bars by General Mills can currently be turned into durable products like playground sets, decking, fencing, and furniture. Recycled PE films recycled into rigid durable goods is a likely place for the MBOLD coalition to start before advancing to a true circular system of food grade film-to-film.

Recyclable store drop-off polyethylene film used in Nature Valley granola bars by General Mills can currently be turned into durable products like playground sets, decking, fencing, and furniture. Recycled PE films recycled into rigid durable goods is a likely place for the MBOLD coalition to start before advancing to a true circular system of food grade film-to-film.

“It unlocks what I’ve been calling the Holy Grail of film recycling, which is full film-to-film circularity,” says Pat Keenan, R&D principal engineer at General Mills and member of Packaging World’s editorial advisory board. “It allows brands to design their film packaging in a way that it can qualify in recycling streams. And once it’s been used as a package and collected for recycling, a reprocessor working with a converter can clean that recycled film material—potentially to food-grade quality—and then turn that right back into a film. Ideally, it would be very similar to the way PET bottles function today. They’re bottle-to-bottle, only this would be film-to-film.”

While food-grade film-to-film is in the partnership’s crosshairs, the reality is more of a stepwise progression. But what’s important is that, in this specific case, all the requisite stakeholders in the supply chain are not only working in parallel toward the same goal, but they’re also actively collaborating all the way around the circle—from brand, to retailer, to consumer, to hauler, to recycler, to converter, and back again to the brand. If the MBOLD coalition fulfills its promise, it could be a transformative circularity model that’s reproducible elsewhere.

Nuts and bolts of a regionally circular recycled film model

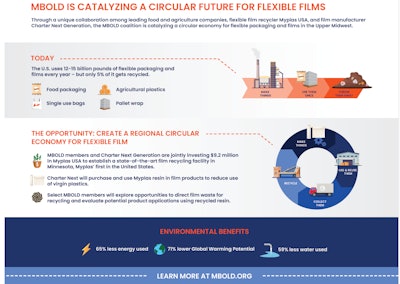

The MBOLD-led coalition unites leading global businesses and research institutions to create a regional circular economy for flexible films and packaging materials in the Upper Midwest. Current members of MBOLD include General Mills, Schwan’s Company, Target, Ecolab, Cargill, Land O’Lakes, and the University of Minnesota. These and other stakeholders are collaborating across the value chain with film recycler Myplas USA, Inc. and film converter Charter Next Generation (CNG) to create a circular economy for films that otherwise may not be recycled.

This new initiative will expand the film recycling infrastructure and the supply of recycled resin for use in new products, reducing greenhouse gas emissions by their regionality and limiting waste. With investment from MBOLD members and other stakeholders, Myplas USA will establish a state-of-the-art flexible film mechanical recycling plant in Minnesota, its first in the U.S. Slated to begin operations in mid-2023, this new 170,000-sq-ft mechanical recycling plant aims to recycle nearly 90 million pounds of low- and high-density polyethylene (LDPE and HDPE) packaging and film annually, when at full capacity.

The U.S. uses 12 to 15 billion pounds of flexible packaging and films annually, including select food packaging, shopping bags, shrink wrap, pallet wrap, e-commerce mailers, lawn and garden bags, and hay bale wrap, among many other products. But only an estimated 5% of flexible films used in the U.S. are recycled each year, with the rest being landfilled, incinerated, or released into the environment as litter.

“We are building a regional ecosystem to support circular approaches for flexible film,” says JoAnne Berkenkamp, managing director of MBOLD, an initiative of GREATER MSP [Minneapolis-St. Paul] Partnership. “By working together, we are catalyzing a new circular economy that will expand access to film recycling in the Upper Midwest, increase the supply of recycled resin for use in new film products, and cut emissions.”

The initiative includes a combined $9.2 million equity investment in Myplas USA by lead investors General Mills, Schwan’s Company, and Wisconsin-based film converter CNG, plus supporting investors Target and water-waste reduction specialist Ecolab. Myplas’ new film recycling plant will be in Rogers, Minn., northwest of Minneapolis, and will employ about 300 people.

Compared with virgin plastics, studies show that use of recycled PE resins offers significant lifecycle benefits, including a 65% reduction in total energy used, a 59% reduction in water consumption, and a 71% reduction in global warming potential.

Building demand for recycled PE resin is also key to a thriving circular economy. To that end, Charter Next Generation will purchase recycled resin from Myplas for use in a variety of food, industrial, and healthcare film products. MBOLD members Cargill, General Mills, Schwan’s Company, Land O’Lakes, and the University of Minnesota will evaluate potential product applications using recycled resin with CNG. Land O’Lakes, Cargill, Schwan’s Company, and the University of Minnesota will explore opportunities to direct film waste to Myplas USA for recycling once the plant is operational, providing essential inputs for the recycler.

The Alliance to End Plastic Waste and Closed Loop Partners are each providing multimillion-dollar debt financing to Myplas USA to support development of their new Minnesota recycling facility. The Minnesota Department of Employment and Economic Development is also supporting Myplas USA through $1 million from the Minnesota Investment Fund and $450,000 from the Minnesota Job Creation Fund.

Stakeholders pull in unison where they overlap

Conjuring a film-to-film circular economy out of thin air requires stakeholder coordination and parallel, contemporaneous work. Instead of the aforementioned mutually exclusive stakeholder silos, imagine the MBOLD model more like a Venn diagram, with shared goals and parallel projects at the intersection of any two rungs of the ladder.

“What makes this [project] different is that we’re banding together,” says Apurva Shah, director of strategic partnerships, CNG, referencing a graphic of the MBOLD model, above. “We are on the film manufacturing, or ‘making things,’ link of this circular supply chain, but we also are very much invested in helping Myplas be a successful recycler to supply us. And we’re invested in helping General Mills, Schwan’s, and all the other partners we supply to use [the films we convert] at scale. By caring and supporting each side of that circular diagram, I think that’s what makes this different.”

According to Shah, what initially got CNG excited about the project and brought his company to the table was seeing Myplas’ original Cape Town, South Africa, facility. He says it’s in a league of its own (until the Minnesota plant is completed in mid-2023, at least) in producing unusually high-quality PCR material.

“We’ll be working with Myplas behind the scenes as the equipment comes in to do initial runs and proof of concepts,” Shah says. “That’ll be going on as soon as equipment’s installed, as we start looking at the different qualities of the bales that they’re bringing in and categorizing them.”

In the PCR space, there are three primary categories: grade A, grade B, and the grade C PCR. Shah says CNG will strive to make sure they’re using A and B quality, and Myplas’ technology is uniquely capable to provide it.

Reciprocally, CNG is preparing its organization to be ready for Myplas’ PCR output. That means putting in the right assets to be able to extrude films with high PCR content. The company already has a large installed base of film lines that can run high-content PCR, but Shah says it’s continuing to expand it while working with Myplas on the build of their facility.

“We’ll be working together to shape what that looks like and make sure Myplas is set up for success when they start up,” Shah says.

Meanwhile, General Mills and Schwan’s are preparing their organizations and their packaging teams to use PCR. This is a journey in and of itself. Both are completing risk assessments, trials, and validations, and they are investing both cost and energy into preparing the organization for using more PCR. And they’ve signed commitments with MBOLD to help supply Myplas with scrap film from their back-of-house operations to help feed the beast with a plastic input. The same is true of retailers, whose back-of-house operations produce significant scrap film, by way of shrink bundles and pallet film.

“We all need to help Myplas be successful. MBOLD is asking the brands to sign a letter of commitment to supply plastic scrap, that’s critical,” Shah says. “And [CNG] helping Myplas develop PCR resins that are ideal for film to be used with high-PCR content, that’s where we come in and collaborate between our two companies. Again, that’s what makes this project different. We are all doing what we do well and what we need to do, but we also put some care, some stake, and some energy in helping our partners on the left and right side of us in the supply chain to be successful as well.”

Sure enough, brands like General Mills and Schwan’s are combing through their respective product and packaging portfolios—which are collectively quite broad based on all the different categories they participate in—looking for opportunities and seeing where they can add PCR today.

“And if you think about it from a brand or business perspective, before you go out there and make a sustainability commitment, you want to make sure you have a consistent high-quality supply, because you don’t want to come out with something like that and then need to reverse,” says Dave Chmura, R&D manager—Snacks, at General Mills. “And so that’s what this partnership also helps us with. We are now well tapped into a consistent source of PCR. We’re basically going through and identifying where we can use the material, and that’s where Apurva [Shah] and CNG are a huge help because they help us with the applications.”

Keeping the beast fed: collecting plastic film inputs for the recycler

Once operational, Myplas will need a consistent source of film inputs to generate new PCR. There’s a lot of potential with non-food-contact packaging, particularly at the intersections between CPG, intermodal logistics, and retailer. Think of all the back-of-house stretch wrap and pallet wrap that goes into the supply chain that consumers never see. MBOLD asks the stakeholders in this segment of the supply chain to commit to supply Myplas with scrap film content.  Cereal liners for General Mills brand Cascadian Farms are made with recycled content liners that are also recyclable.

Cereal liners for General Mills brand Cascadian Farms are made with recycled content liners that are also recyclable.

“Over the next year or two, with MBOLD companies supporting them, Myplas will be working on how to really set up sourcing that raw material, so we have a steady stream going into the Myplas facility,” says Julie Simonson, PhD, VP of R&D and product innovation at Schwan’s. Meanwhile, she says the brands and CNG will be “doing all the R&D work that will set us up for incorporating the PCR that’s coming, and eventually incorporating it into our packaging. Goals in the next two years are to get the plant operational, get the supply going and do the back-end of that circular economy, and get it into our products and packaging.”

Not related to consumer packaging, agricultural films used in applications like storing and drying hay, often contaminated with dirt and stones from the field, will be a consistent input. MBOLD members from the agricultural sector, like Cargill and various Minnesota and Wisconsin agri-biz NGOs, have made commitments here.

“And it’s worth noting Myplas is a recycler. They’re not a hauler. But that hauling component is something that they’re taking leadership of,” MBOLD’s managing director Berkenkamp adds. “And in some cases, that may be worked out collaboratively between a generator or supplier of that waste film and Myplas, in the case of those kinds of commercial and industrial sources.

“For the MBOLD coalition as a whole, part of what will happen in the next 12 to 18 months is looking more closely at these opportunities of waste supply [back to Myplas as feedstock] as well as use and demand applications for the recycled resin,” she says.

Finally, from the consumer stream, expect in-store drop-off plastic film grocery bags and PE plastic pouches to be another input stream at some point—hopefully a growing one, though consumer adoption is slow. With a growing commitment to mono-material films among flexible packaging suppliers, this stands to be an increasingly reliable input. Consumer education is still needed, however.

Third-party certifications aim for consumer buy-in

The maddening Catch 22 behind many of these circular economy efforts is that they’re ostensibly driven by a consumer demand for more sustainable packaging. But there’s a lack of awareness of recycling streams for flexible film circularity. The store drop-off stream has been a highly functioning, self-sustaining means for consumers to recycle PE films, but there is a general lack of awareness. It is in the best interest of the industry to build awareness of this program.

All converters, brand owners, and sustainability NGOs can do is keep their foot on the gas when it comes to consumer education, while ensuring third parties are vetting and certifying all legitimate practices. Expecting a greater number of consumers come around to better recycling behaviors around films, all of the stakeholders intend to attain third-party validation that’s recognizable to the public.  Recycling and recyclability instructions on Cascadian Farms cereal boxes come from third party certifier how2recycle, from the Sustainable Packaging Coalition (SPC). This certification, and education, is important in gaining consumer adoption and compliance now and in the future.

Recycling and recyclability instructions on Cascadian Farms cereal boxes come from third party certifier how2recycle, from the Sustainable Packaging Coalition (SPC). This certification, and education, is important in gaining consumer adoption and compliance now and in the future.

“We are working on getting all of our facilities certified and then also certifying specific films with the PCR content. It’s just incredibly important for there to be full chain of custody and transparency,” CNG’s Shah says. “That’s part of the work we’re doing over the next 12 months. We have a couple of our sites that are already fully certified through a couple different agencies, but that’s absolutely on our radar. Myplas will have its own certification process, one of the key ones being through the Association of Plastic Recyclers [APR] to be a certified source of PCR.”

From a brand perspective, these certifications are also musts, but entail a different set of standards.

“Today, for us, that’s the How2Recyle label. And we follow the testing protocols whenever we use that label to run that through How2Recycle from the Sustainable Packaging Coalition [SPC]. And then there’s an APR protocol as well,” adds General Mills’ Chmura.

Crawl before you walk

Every stakeholder that Packaging World spoke to among the MBOLD coalition agrees that the ultimate goal is to create a film-to-film circular regional recycling ecosystem that’s capable of producing food grade-quality materials. But all parties involved were very clear that a stepwise approach of film to durable goods to eventually true circularity is the best approach.

First, not all film materials running through the Myplas facility will be perfect, grade-A PE that’s destined to be returned to its film form. Lower grade flexible films could be recycled (sometimes called downcycled) into carpeting, or durable outdoor products, like decking, lawn chairs, or swing sets, in the form of HDPE.

“For non-food-grade PCR films, there’s a pretty wide swath of applications. Certainly trash bags are one area, and lots of your home care products,” Shah adds. “Think of the wrapping around toilet and tissue overwraps, or of various back-of-the-house bags that are used to move different products there. There are even some categories that have historically used food-grade PCR, but don’t necessarily need it. We’re kind of doing evaluations on that. A good example would be your pouches for various detergents and liquid packaging that are used in the home. There are actually a lot of applications that don’t require food-grade PCR, but have historically used food-grade PCR because that’s what was widely available. That whole reinvestigation of the use of films is kind of the journey we’re on right now to start delineating what really needs to be food-grade and is direct food-contact, and what’s not.”

For the General Mills and Schwan’s of the world, though, the goal is food-grade films from PCR, for instance in the case of a PCR PE film liner in a cereal box.  Back-of-house operations at many retailers involves a lot of pallet wrap films that need to be discarded or recycled. Details aren’t yet firm, but retailers involved in the MBOLD coalition could take an active role in hauling used back-of-house films to Myplas to augment the rPE feedstock and help Charter Next create new films.

Back-of-house operations at many retailers involves a lot of pallet wrap films that need to be discarded or recycled. Details aren’t yet firm, but retailers involved in the MBOLD coalition could take an active role in hauling used back-of-house films to Myplas to augment the rPE feedstock and help Charter Next create new films.

“Even within the non-food grade PCR, we’re looking across our portfolio to try to find applications to use the material. And that’s the beauty of having CNG, one of our trusted film partners, in the relationship with us,” Chmura says. “We can look at things such as our shrink bundling films in these types of applications to get started for the non-food grade PCR. It’s not like this is a magic process where we flip a switch, and all the sudden food-grade films are being collected and recycled. This is really building for the future, but our goal is still food-grade.

“Hopefully, the day comes where that is happening more at scale, and not just in store drop-off,” he concludes. “That’s the vision of many different people that it expands collection, to make it easier for consumers. But this is one step in that supply chain and we’re positioning ourselves for the future to have access to a supply to fulfill the future demand for PCR.”

Piecing together the puzzle

Schwan’s brand Red Baron uses PE film to shrink wrap its frozen pizzas. A future state of this product could use food-contact rPE via the MBOLD coalition supply chain.

Schwan’s brand Red Baron uses PE film to shrink wrap its frozen pizzas. A future state of this product could use food-contact rPE via the MBOLD coalition supply chain.

“I liken it to a thousand-piece puzzle. Where are we on this puzzle? We’ve dumped out all of the pieces on the table and found the corner and some edge pieces, and we’re building off them right now. What you see now is just a few pieces that have been put together, but there are many more pieces that have to fall into the puzzle for this thing to truly go at full speed, for us to complete the whole puzzle. We’re very early in the process, but we have established a cornerstone, a footing. This is really something that is the first step, the first pieces of that puzzle coming together. And we’re really hopeful that more of the pieces come so that we can have a full picture in a full circular economy.”

Berkenkamp adds: “The goal is to create a regional ecosystem of business engagement to help a circular economy drive for polyethylene film waste. And the secret sauce for us has been the commitment to collaboration among MBOLD members like Schwan’s and General Mills and others, CEO-level leadership, and then first-rate value chain partners in Myplas and Charter Next. We all understand the win-win nature of this kind of collaboration.

“I would also say we look forward to other businesses and institutions joining us on this journey, and we hope that MBOLD’s approach will inform and inspire other circular economy efforts around the country. And we’re happy to share what we’re learning as this journey unfolds.”

Concludes Mikol of Schwan’s, “As Pat [Keenan of General Mills] says, film-to-film circularity, and eventually food-grade film-to-film circularity, really is the Holy Grail. But where we’re at now is maybe just the base of the cup. We have a ways to go to get the whole chalice built. This is a very exciting first step, but there are still many more steps ahead.” PW