Good things come to those who wait.

In the case of serialization in pharmaceutical packaging… yes and no. With little more than a year left to meet the 2017 U.S. deadline for manufacturer serialization, companies that haven’t started will be under immense pressure. But there is an upside for companies who have waited: they have opportunities to learn from others’ mistakes and success stories.

The industry is still brimming with confusion and fear regarding serialization, especially among CMOs who package products for many customers. In fact, a recent survey of CMOs found that 95% are afraid of losing business if they don’t comply.

To help foster collaboration, Optel Vision and Supply Chain Wizard recently held their first Serialization Roundtable for CMOs to encourage discussion between pharmaceutical manufacturers, CMOs, and vendors. The event creators urged attendees to remember that the regulations are ultimately about protecting people, their own families included.

CMO-specific challenges

The largest generic house in the world, Teva Pharmaceuticals, oversees production of 64 billion tablets/year and manages more than 700 CMOs. The company is well versed in evaluating serialization readiness. “You can’t wish your way to success,” said Vivian McCain, Teva’s VP of Third Party Operations, Americas, “You have to have a plan.”

The challenges of serialization projects for CMOs fall into three main buckets: financial, technical and operational.

The question of who will finance a CMO’s serialization efforts is truly the elephant in the room because the responsibility does not fall squarely on either the CMO or the pharma company. Dr. Evren Ozkaya, Founder and CEO of Supply Chain Wizard, said the CMO might pay for the upfront cost and then pass on a unit cost increase to the customer. He has also seen an increase in cases where the customer pays for serialization when the CMO has a dedicated line.

On the technical side, CMOs and customers must set up standards and come to agreements about responsibilities for packaging and label design. Both parties must ask whether they have the right resources, equipment and IT infrastructure, and there has to be discussion around how batches will be released, how exceptions will be managed, and who will store master data. Though there may be confusion about who owns the serial numbers, Supply Chain Wizard’s Priya Gopal clarified that the party that owns the product (i.e. the pharma company) should own the serial numbers, not the CMO.

In particular, McCain offered advice for CMOs who want to maintain or grow their market share:

There is communication hesitancy on both the CMO and customer sides. CMOs must be proactive in reaching out to pharma customers to ask about their requirements. If you don’t have internal resources to manage serialization, you have to get help. But there is a caveat: serialization service providers are limited in their capacity as well. And Ozkaya noted that internal serialization talent may be poached by other companies or may opt to start their own business, therefore getting outside help to ensure consistent support might be a good strategy for many.

Factor in time for efficiency losses. “You will lose efficiency when you do your pilots and upgrades,” said McCain. When I come into your shop to ask, ‘When will I get my product?’ I need to know you’ve factored that in and given a realistic date, because my customers need to know that when I make a promise, they are going to have it on that date.”

He also warned that there is often a gross underestimation of resources needed to manage the project, and that serialization should not be given as a development opportunity to a less-than-stellar employee.

Pilot projects

Experts and end users all agree that pilot studies are immensely important. Aladin Alkhawam, Director of Packaging Operations at PAR Pharmaceutical was on hand to educate attendees on rollout and pilot strategies and offer valuable lessons learned from PAR’s implementation:

Ensure testing is performed early on (ideally during Factory Acceptance Testing) for newly added printers. If functional or integration problems are discovered late, you may need to add addendum protocols to IOQ tests and/or replace the equipment.

Have OEM personnel available on-site during the line setup to help troubleshoot possible integration issues. Reaching out to vendors once installation has already begun can result in unnecessary delays. Resolution strategies with OEM personnel should be documented and used for future startup efforts.

Review alarms details. A yellow or green light may flash in a situation where red is expected. “It’s good to go through those details early on to discover those discrepancies,” Alkhawam explained. Seemingly small details can delay line startup and validation approval.

Don’t ignore documentation! Equipment and software setup may command a lot of attention, but the document management methodology must be aligned with the vendor to track all inter-related documents.

Consider inventory before the pilot begins. Alkhawam said they were careful about which line they chose for the pilot study, which was aided by Supply Chain Wizard. “First, we made sure whatever runs on that line is validated to run on other lines. Second, we had to build some inventory. The lines could be down as much as eight to 10 weeks,” he said. “You have to look at what runs on what line. You may want to start your pilot with the line that runs the least product and then build from there.”

Varying equipment needs

CMOs must be able to address a variety of packaging needs for their customers. They often accommodate multiple package sizes and configurations on a single line, deal with artwork changes, and have to ensure that employees are trained to handle all the different packaging scenarios. They must also be able to interface with multiple customers and serialization servers in an efficient manner.

JP Allard, Global Serialization Program Manager at Optel Vision, suggests that CMOs “throw the ball first” by defining their limitations early on, or risk being at the whim of many different customers’ requests. These limitations include print area size and location, maximum case size, EPCIS report type, and tracking code location. Tracking codes are temporary numbers that associate bottles with a given serial number and are read during the aggregation process. Allard suggests that unless a line is dedicated to one customer, CMOs apply the codes on the bottom of bottles because topserts and caps vary more between customers (they may not always have enough room or be flat enough for proper code application).

There are also serialization technologies,like flipping push-plates within case packers, which help CMOs accommodate varying package sizes. Unlike push-plates with built-in inspection (which work well for lines that handle one case size),a flipping push-platerotates 90 degrees once the push is performed to allow the camera to take a picture of the cartons inside the case. This optioncan be retrofitted to existing equipment toprovide flexibility, as it eliminatesthe need for the case to be a specific size.

Investing in IT

Historically, IT has not been given the attention it deserves. But being an integral and core part of serialization, IT can no longer be feared or underestimated. Burak Tiftikci, Managing Partner at Supply Chain Wizard, explained that sufficient budget and IT training time are critical. “When your serialization system is down, it’s like a power outage,” noted PAR’s Rich Walton. “You have to have in-house knowledge beyond consultants to get the line back up.”

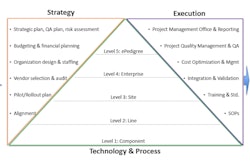

Tiftikci also advocated that companies view serialization as a business capability because the approach of simply meeting specific regulatory requirements can lead to a higher likelihood of constant integration enhancements and modifications in the future. He added, “You can always ‘dumb’ down the richness of data to meet a regulatory requirement. However it is exponentially more challenging and additional effort to drive richness from a generic and highly summarized dataset.”

Along these lines, it may make sense to add aggregation now, although it is not a U.S. requirement until 2023 (there are customers and countries who want aggregation now). Some companies find that it can be helpful in recalls and returns, while some add aggregation now to avoid shutting down and going through another qualification later. One case presented by JP Allard showed that adding aggregation at a later date cost 27% more than performing the upgrade during serialization implementation. Of course, postponing aggregation means taking advantage of future equipment upgrades, so this must decided on a case-by-case basis. A blended strategy—adding some aggregation now, but holding off on aggregation on all lines—may be a good option, given the rate of change of technology and regulations.

Roundtable success tips

• Use lunch-and-learn segments to get senior management and cross-functional teams on board.

• Don’t be shy about asking for help. One presenter said that one of the best decisions they made was to reach out and get help from consultants. You can have consultants help you present your case to upper management—the message may come across better from them, especially by leveraging industry lessons learned.

• Educate the people on the floor—they will react to the changes more positively. Get everyone to understand what is coming their way and the importance of serialization.

• Expedite validation by leveraging validation documents the vendors have, bringing in extra resources (internal or consultants), and adding double shifts, if necessary.

• Include distribution/supply chain pilots. Everyone is focused on packaging pilots, but there is a lot to learn with respect to changes in IT infrastructure and solutions you put in place.

• CMOs who become trusted partners may gain additional market share. Pharma companies with legacy lines may opt to send those products to CMOs instead of upgrading to serialized lines.

Roundtable areas of concern

• CMOs are generally smaller businesses than their typical customers, so there are resource constraints. It’s hard to accommodate a serialization project when everyone has a day job. You need a good leader to spearhead the effort with enough IT and Packaging/Engineering resources.

•There is concern about managing serialized and non-serialized product concurrently. One presenter mentioned the idea of serializing all products to make it easier at the packaging line level in terms of SOPs and training.

• Data management brings up many questions. Does a third party maintain the enormous amount of data? Who manages change control? What safeguards are in place around this sensitive data?

• There are general concerns about the data exchange itself. What data should be exchanged and how? What events trigger data exchange?

The bright side of serialization

Although deadlines loom and the implementation process includes many hurdles, there are positive side effects from serialization efforts beyond drug safety. As Ozkaya pointed out, a well-run serialization program can minimize compliance risks while providing unprecedented supply chain visibility. The increased data and communication opens doors for collaboration with partners, along with better forecasts and decision-making. Unit-level root cause analyses and cost tracking will provide insights into product recalls and pricing changes. Situations where customers buy a product at a discount, and return it at full price can be avoided, as companies can track the purchase price at unit level much more easily. Beyond data perks, the regulations can be used as a justification to make changes, driving equipment upgrades that will increase efficiency after the ramp-up period.

McCain hopes that industry collaboration among pharmaceutical manufacturers and CMOs will boost serialization capabilities. “We need to collectively find a solution, because we are out of time.”

Watch a video covering the event.